Electric Vehicle Dynamic Simulation: Using Modelica Methodologies to Model EV Pickup Attributes

Exploring electric vehicle dynamics can be a difficult exercise in multi-objective optimization. Systems are more complex with every new generation of vehicles, and each component has an effect on the other components. The powertrain department cannot sit in a silo and work solely on their components. They need to interact with other stakeholders, and look at the vehicle-level impact of the features they are adding. Otherwise, there are almost certain to be conflicts between systems and components, leading to expensive last-minute changes.

The solution is to maintain a system-level “single source of truth” shared across all of the departments. But that is tremendously difficult. Different departments tend to rely on different tools and frameworks, making it cumbersome to model the full vehicle for a multiple-attribute study. Keeping those various tools and models in alignment eats up a disproportionate amount of time in duplicated effort. And even then, it can be extremely easy for different teams to move forward without realizing that their model is out of sync.

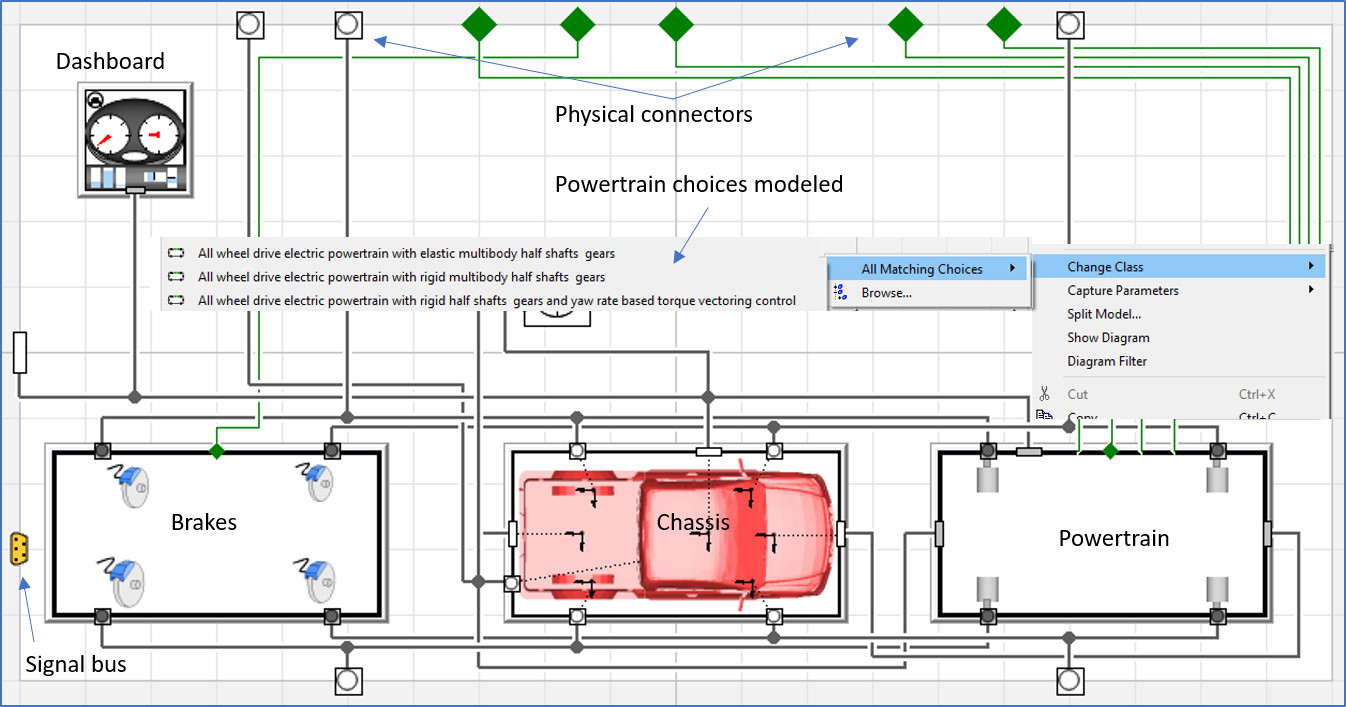

Therein lies the benefit of using Modelica—an open, collaboration-friendly multi-body/multi-domain modeling framework—for building complex shared models. In contrast to using multiple existing tools, Modelica together with Functional Mock-up Interface (FMI), an open standard for model portability, substantially reduce the amount of effort teams need to invest in order to maintain an OEM-wide single source of truth.

Because Modelica is a physical modeling language, teams can combine different domains and 3D multi-body models, enabling them to model all attributes in a single framework. With that single source of truth in place, teams will no longer operate in silos.

Exploring Electric Vehicle Dynamics with Modelon Libraries

Right now, we’re seeing a great deal of enthusiasm for electric vehicles—and correspondingly high expectations when it comes to performance, handling, comfort, and other attributes. But these are complex, multi-domain systems. When siloed development teams make changes that meet their goals, there are often unforeseen effects on other vehicle attributes. In the absence of a system-level model of the vehicle, these can slip by unnoticed. When they’re caught, it’s later in the vehicle development process—necessitating unpalatable trade-offs, or expensive changes. But if those teams are all collaborating on a Modelica-based full-vehicle model, then any one team can create a spider chart, change parameters, and quickly see the impact on all the other vehicle attributes. Unworkable avenues can be spotted earlier, and alternatives explored before too much time is invested in a dead-end solution.

As a proof-of-concept, and to support future component and controls development, my colleagues and I took publicly posted data from a commercially available EV pickup truck (the Rivian R1T) and used that to model the vehicle using a Modelica-based framework supported by Modelon’s Vehicle Dynamics Library, Electrification Library, and Liquid Cooling Library. Our model included detailed systems analysis of the vehicle’s battery, traction motors, driveline, and chassis(suspension/brakes/wheels/mounts). We then had a single, unified, multi-component model of the vehicle.

In order to confirm that our model was accurate, we ran simulations to confirm that our modeled vehicle behaved as per the manufacturer’s advertised specifications. For example, we saw that our model’s range matched the OEM’s advertised range (presumably based on real-world performance by physical vehicle prototypes).

More importantly, in terms of collaboration and cost reductions, this Modelica-based model maintained its accuracy even as we selectively lowered the fidelity of some elements—improving simulation speed by a factor of 9x.

Creating a System-Level Single Source of Truth

With access to such a model, a powertrain design team working to increase the vehicle’s range would be able to quickly see if their modifications damaged performance and handling, rather than being blindsided down the road with a host of new problems to address. But the speed and accuracy of this model makes it even more valuable. Individual departments can use such a model to quickly explore the elements of electric vehicle dynamics important to their work, without getting bogged down by an overly detailed model of other systems—and still be confident that they’re seeing an accurate representation of how their work will impact other departments.

And that’s just the beginning. Such collaborative multi-body models open whole new design avenues. We’re currently using this model and a set optimization routine to identify the optimal vehicle parameter configuration for this EV pickup, one that gives the best results across all five attributes (range, performance, drivability, handling, ride comfort).

To learn more about how to build complex multi-domain/multi-body models using Modelon libraries, contact us to schedule a demo!