Thermal power generation needs to transform in the coming years. Today, burning fossil fuels accounts for roughly 90% of all carbon emissions. Although thermal power plants could, in theory, generate heat from any fuel source, most still rely on burning coal, oil, or gas—which together are used to meet most of the global electricity demand.

The energy industry widely agrees that fossil fuels are an eventual dead end. Equipment manufacturers and utilities have shifted their long-term strategy accordingly, setting new lower emissions targets and striving to squeeze greater efficiency from each component. Even if plants embrace heat sources that produce fewer greenhouse emissions, the industry would still need to reevaluate its current approach to thermal power generation at a fundamental level.

For example, on hot days (when electricity is most in demand for cooling homes and buildings), the ambient air and water that power plants use for cooling can become too warm to serve this function efficiently. Since those plants cannot dissipate heat quickly enough, they must decrease power generation, regardless of demand. According to some estimates, making up for this power generation shortfall will require building 40 to 60 additional average-sized thermal power plants for each added degree of global average temperature increase. Given that they’re the areas most impacted by global warming and the technologies favored in those regions, it’s reasonable to assume that much of the additional capacity will rely on burning coal or other fossil fuels.

Increasing reliance on fossil fuels and coal is not tenable. Organizations have rightfully prioritized reducing CO2 emissions wherever possible.

Augmenting existing thermal power infrastructure is highly complex. Engineers and energy producers want to create efficient, utility-scale energy generation and storage solutions and explore new control strategies to sustainability doesn’t compromise reliability.

Right now, even innovative teams need more tools to effeciently bring these projects to market.

Learn how Modelon helps designers, engineers, and power plant operators use model-based design and dynamic modeling to tackle these large-scale projects today.

An Overview – Addressing Climate Change with Thermal Power Generation and Storage

The energy sector is a crucial contributor to climate change and, thus, an essential part of the solution.

While renewable energy is vital to a sustainable, decarbonized energy future, it is not a cure-all. Existing thermal power plants continue to meet demand and support the stability of power systems. Augmenting these existing systems and balancing production as renewable energy sources are deployed moving forward is critical.

Updating existing systems is a delicate balancing act. How can we ensure that aging infrastructure delivers the right energy at the right time? What strategies do we have for using fluctuating renewables at scale? How will we address the power storage and charging challenges power plants experience? What new control strategies can deliver more power with greater reliability?

Long-term planning is essential in terms of risk mitigation. Increasing control reserves and efficiency, designing more reliable control strategies, and mitigating previously unpredictable failure scenarios are all essential tasks related to decarbonization and incorporating renewable energy.

Even straightforward changes like increasing the thermal efficiency of individual components hold the potential for long-term gains and impressive reductions in emissions over time–if engineers have the tools to make sound design decisions.

The Business Case – Using Comprehensive Physics-based Modeling for Thermal Power Generation and Storage Systems

By adopting more comprehensive physics-based dynamic models, engineers can take on more complex and ambitious tasks today.

For example, many thermal power plants want to explore cogeneration (i.e., “Combined Heat and Power” or “CHP”) strategies. With cogeneration, a thermal power station captures the waste heat generated during electricity production and uses it for district heating (or some similar application)—in effect, getting a “two-for-one” deal on heat and electrical generation. The efficiency of such an arrangement is extremely promising.

However, cogeneration has yet to be broadly adopted. Cogeneration requires much greater controller complexity and tuning. Without good dynamic modeling, the only option to update existing plants is risky, expensive testing run on a live plant.

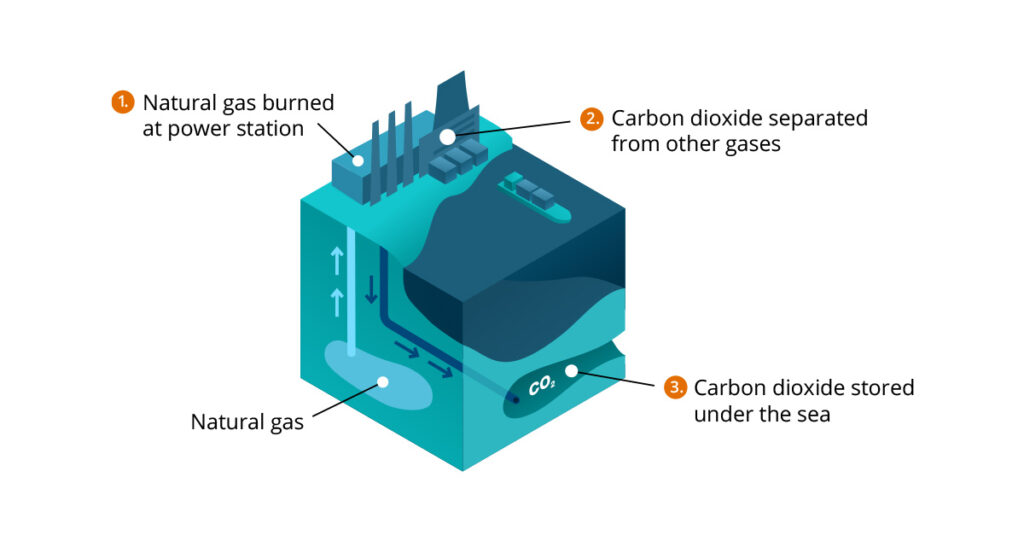

Carbon Capture and Storage (or “CCS”) is another area where engineers could go further if they had the proper support. This is especially true with CCUS (Carbon Capture, Utilization/Usage, and Storage), which offers similar “two-for-one” efficiency. With CCUS, carbon is repurposed as a feedstock for plastics, concrete, or fuel production instead of simply capturing and storing emissions.

To achieve this, engineers need tools to estimate the cost of CCS/CCUS, enable stable CO2 removal rates, and explore strategies for minimizing potential drains on the power plant’s core function (e.g., reduced power production or constraints on transient operation).

By embracing comprehensive model-based design and system simulation tools, power companies can assess the options for meeting CO2 emission reduction targets and deploying cost-efficient implementations of new power generation, cogeneration, and storage strategies.

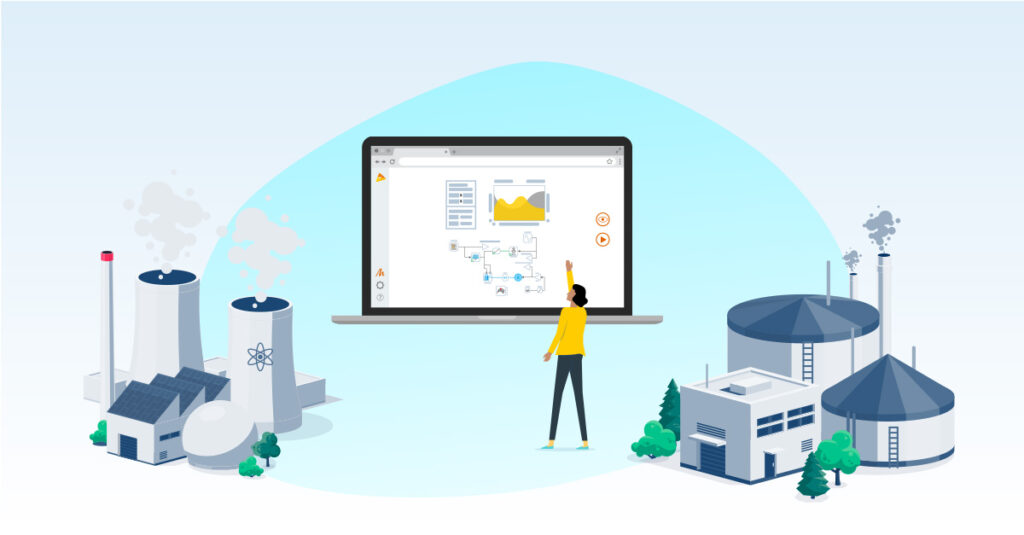

The Solution – Modelon Impact for Thermal Power Generation and Storage System Development

Modelon Impact is a cloud platform for designing, simulating, and analyzing physical systems using model-based design. Through its Thermal Power Library, Modelon Impact provides a comprehensive modeling, simulation, and optimization framework for thermal power plant operation (including control systems), covering both new and traditional energy sources.

Modelon Impact offers a comprehensive suite of tools, libraries, tutorials, and customizable commercially validated components specific to power generation and storage systems. These commercially validated components include generators, turbines, boilers, thermal storage systems, and ready-to-use models for various energy sources (e.g., concentrated solar power, gas, coal, nuclear, etc.), district heating systems, thermal cogeneration power plants, and more.

If projects demand further customization or have unique qualities you need help capturing in your models, Modelon’s system design and simulation experts are here to help.

Beyond modeling what you have now, Modelon Impact is built to help you evaluate novel concepts for the future using:

- Templated system models simplify the modeling of new plant concepts while allowing for unique layouts

- Zero-risk testing and development of start-up sequences, plant-wide control design, and emergency scenario simulation-controller tuning

- Numerically efficient and robust fluid models for fast simulation and dynamic optimization of large-scale systems

As a cloud platform, Modelon Impact makes it simple to collaborate across your entire organization (including non-specialists and those with limited engineering or programming experience) and with external partners. This comprehensive, dynamic physics-based modeling approach allows you to enjoy added insights. With multi-fidelity models, teams enjoy greater latitude in exploring affordable, efficient, scalable, and dispatchable energy storage solutions using standard components and materials.

Library

Thermal Power Library

Case Study

Improving Control Strategies for Thermal Power Plants

The Use Case – Physics-based Dynamic Modeling in the Field

Thermal engineers are already using Modelon Impact to increase the efficiency of their efforts. For example, Babcock Power uses dynamic models to study the replacement of coal in existing boilers. (https://asmedigitalcollection.asme.org/POWER/proceedings-abstract/POWER2023/87172/1167509). Also, utilities use system simulation to adapt their existing plants; e.g., Stadtwerke Rostock AG used a dynamic model of their combined-cycle gas-turbine power plants built with Modelon’s Thermal Power Library (TPL). The dynamic model was initially intended for exploration and optimization of cogeneration opportunities. However, that same model was also used to evaluate and re-engineer thermally stressed components for optimal flexibility and investigate the best way to integrate thermal heat storage into their energy system.

Modelon Impact’s Thermal Power Library is also being used to design more flexible and decarbonized power plants that effectively integrate CCS technology for lower power plant emissions and increased thermal efficiency. In almost any power generation scenario, engineers can use Modelon Impact to reduce commissioning time by accelerating control tuning. By developing their preliminary control design with the model of the plant in advance, there is less adjustment and iteration in the field. A validated controller design substantially reduces in commissioning time and unpleasant surprises once the plant is up and running.

Resources

Customer success is always our top priority. Over the past two decades, we’ve distinguished ourselves by delivering exceptional service and expertise, earning a reputation as a trusted partner in many industries.

We know that a complex new tool can be daunting. That’s why Modelon regularly releases easy-to-follow tutorials and guides on the Modelon Help Center. Need further support? Our experts are here to help you and your team move forward.

Case Study

ENGIE

Webinar

Integrating Carbon Capture and Storage Technology

Blog

Integrating Carbon Capture and Sequestration (CCS) with Natural Gas Combined Cycle Power Plants

Ready to make an impact with system simulation?

Get in touch today to see how Modelon Impact can help you with your system simulation and product design journey.