Modernizing Fighter Aircraft With Open-Standard Technology

Saab integrates Modelon into their MBSE approach for open-standard technology services and project delivery.

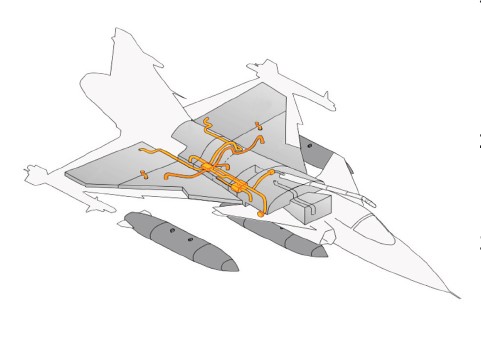

Saab’s Gripen Aircraft

Gripen made history in 1988 for being the first multirole fighter aircraft developed in Sweden to take flight. With the capability to effortlessly transition through altitudes, positions, and speeds within a matter of seconds, this powerful aircraft quickly became a force to be reckoned with. Since the conception of the original Gripen, Saab has been tasked with delivering versions of the fighter that are each more technologically advanced, powerful, and faster, than its predecessors. However, the level of complexity and integration of the Gripen was quickly outpacing Saab’s engineering development capacity. Saab needed to figure out how to meet performance demands for their fighter without overwhelming their engineering talent. Because of this challenge, Saab adopted a model-based systems engineering approach in the early 2000s to digitally analyze their fighter and make quicker and smarter product design decisions.

Challenges

Before Saab could start improving upon their Gripen fighter with systems engineering technology, they needed a way to replicate the architecture and behavior of the latest Gripen series within a digital model. This was a tricky undertaking, as each original fighter’s sub-system was created precisely with multiple dependencies. Saab’s model of the Gripen fighter would need to account for the following:

- The rapid temperature and pressure changes as the aircraft alternates quickly between altitudes

- An air cycle cooling system that was sensitive to the surrounding humidity

- The complexity of approximately 15 fuel tanks attached together and their adjustment to changing attitudes of the fighter

After defining their requirements, Saab set out to find modeling solutions they could use to build an accurate physical system and sub-system models of the Gripen. Their solution would need to be able to accurately capture high-fidelity physics as well as integrate with their existing toolset and processes. However, they struggled to find a suitable solution that met both criteria. Many of the solutions they evaluated were too basic to build and simulate a high-fidelity system model or yield conclusive results. As for the solutions that allowed for high-fidelity physics modeling, Saab could not integrate them with their existing set of technologies.

Solutions

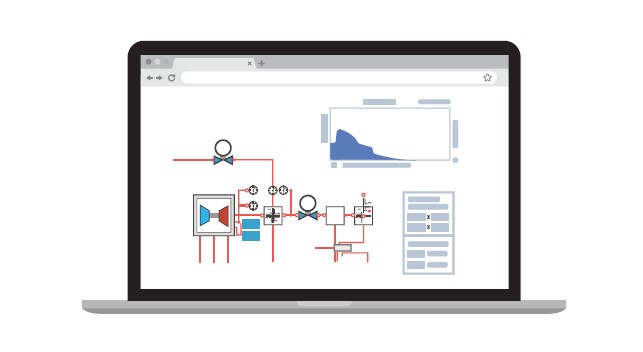

So, what did Saab do when they could not find a modeling solution that fit their criteria? They developed their own – with Modelon’s help. Saab knew they wanted to work with open-standards technology, as they needed flexibility to model current and future technologies. When Saab discovered that Modelon works with Modelica, an open-standards language best suited for accurate physical modeling, they knew the partnership would be a great fit.

In 2005, Saab partnered with Modelon to develop a library that accurately represented the Gripen’s cooling and fuel systems, yielding dependable simulation results. Saab’s simulation team defined the requirements for each library component, and Modelon, leveraging its industry expertise, developed the components to Saab’s specifications. To better assist the Saab team, Modelon developed system models based on the Gripen’s components, giving Saab’s engineers a head-start.

“The largest benefit of building the model with a dependable library of components was being able to help our engineers think. Our team could more clearly see how a system architecture was laid out and where changes would need to be made.” – Peter Gotenstam, Manager of Vehicle Systems Concept Design, Modeling, and Simulation, Saab Aeronautics.

And it didn’t stop with delivering Modelica library components. Saab and Modelon continued partnering to support the Saab team as the models were deployed into Saab’s engineering workflows. If the Saab team ever got stumped when simulating cooling or fuel systems, they would reach out to Modelon for quick direction on overcoming the challenge. Modelon’s support, along with the custom library, helped Saab create the system models needed to push the Gripen forward. “Modelon’s technology works for us. The models can give us results within the desired ranges of the actual Gripen depending on the use case. This gives us a lot of trust in our product and our design direction.” – Peter Gotenstam, Manager of Vehicle Systems Concept Design, Modeling, and Simulation, Saab Aeronautics.

Results

With Modelon’s expertise and service integrated into their MBSE approach, Saab launched the Gripen E-series in 2018. This new series was a major design update from the original C-series Gripen including new avionics architecture, an increased weapons payload capability, and a more powerful engine.

“If it were not for model-based systems engineering, we simply would not have been able to achieve the Gripen E because the complexity would have overwhelmed us. Now, not only are we able to regain control despite increasing complexity, we’re also able to get to first flight faster with each new version of the Gripen.” – Peter Gotenstam, Manager of Vehicle Systems Concept Design, Modeling, and Simulation, Saab Aeronautics.

As for the custom library, Saab and Modelon evolved the library until it became commercially available to everyone as the Fuel System Library and the Environmental Control Library by Modelon. These libraries are currently integrated and ready to use within Modelon Impact – Modelon’s cloud-based system simulation platform.

Today, Saab continues its collaboration with Modelon. As the demand for onboard electric power increases, so does Saab’s need for integration and understanding of electric power generation. As new electrical loads are added to aircraft there is increased demand to accurately model power supply, distribution, and thermal management. Given Modelon’s broad portfolio, Saab can now rely on readily available physics-based modeling libraries instead of developing new ones from scratch. Additionally, Modelon constantly improves the predictive capabilities of its models based on discussions with its users.

“The recent Fuel System Library offers workflows that can dramatically improve the accuracy of our tank predictions. We are eager to try them out!” – Peter Gotenstam, Manager of Vehicle Systems Concept Design, Modeling, and Simulation, Saab Aeronautics.