Adapting to The Future of Energy Technology with System Simulation

Siemens Energy selects Modelon Impact to integrate advanced energy systems with its existing heat pump technology.

Challenge

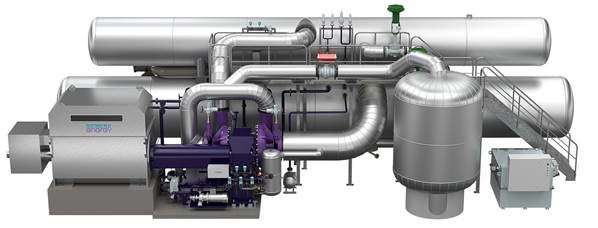

The Siemens Energy heat pump system SHP-C600 ll-established technology that started in the mid-80s. With 50 units delivered and more than 6 million operating hours in total, the system can provide 15-40MW thermal energy for district heating systems using heat sources such as seawater, sewage-process water, outdoor air, and geothermal production. Through these sources, Siemens Energy heat pumps can generate 3-5 times the heat they consume in electric energy.

While Siemens Energy heat pumps are well-established, integrating them into evolving energy systems was proving to be challenging. In the past, energy systems offered steady and predictable operating periods. Now, energy systems have been changing with unprecedented speed which sets new requirements on flexibility. There are many more challenges as energy supply system designers seek to maximize energy output while minimizing ecological impact – two critical asks from consumers.

Siemens Energy needed to improve and further develop its heat pumps to ensure the performance and design of the integrated systems worked efficiently before moving forward with deployment. Changes to the system post-deployment would have resulted in both increased costs and significant time to go to market. In addition, the application of heat pumps into district heating systems is not a ‘one size fits all’ process. Each application is unique, where factors such as climate and system scale force different trade-offs and complex design decisions. Lastly, to ensure maximum energy efficiency, Siemens Energy needed to have a more accurate pulse on the flow and capacities of integrated systems.

Siemens Energy decided to explore system simulation to save on application costs and speed up the development process of its heat pump system design. To prove the value of system simulation, they needed the following:

- An accurate digital process and controller model that captures the complexity of the Siemens Energy heat pumps

- The ability to integrate the model into district heating systems over a wide range of operating scenarios

- Reliable simulation results to help make better product design and development decisions

Solution

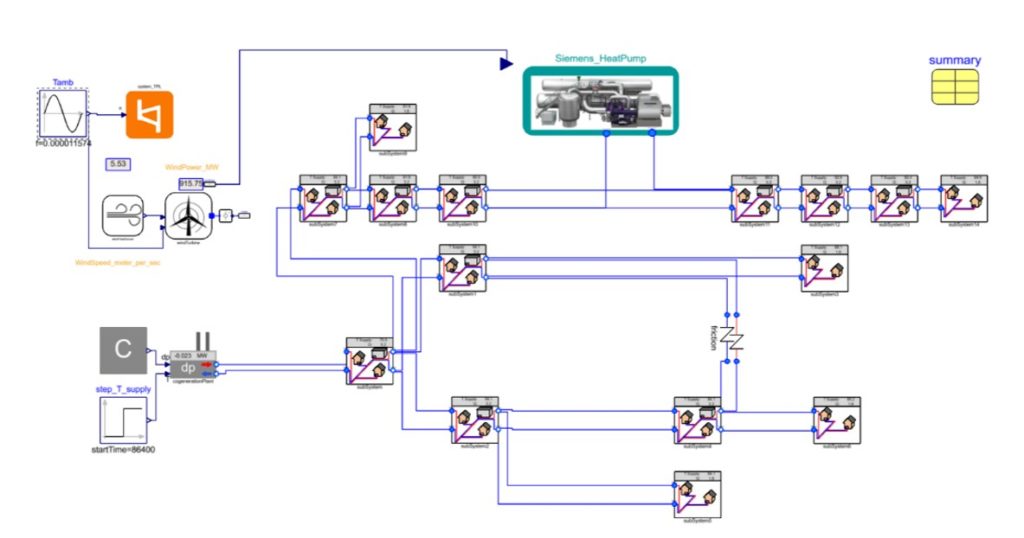

Siemens Energy selected Modelon’s cloud-native system simulation platform, Modelon Impact, to develop a detailed transient heat pump model and integrate it within a district heating network system model in the Thermal Power Library within Modelon Impact. The model represents 125 consumers grouped into 15 clusters with separate load profiles demonstrating the heating system of a city. Being able to simulate different and unique operating conditions to see how the heat pump model works in a district heating system was important for the global Siemens Energy engineering team’s assessment of how the systems would operate. The capabilities in Modelon Impact enabled the Siemens Energy engineering teams to collaborate and improve upon their heat pump design. Emil Hell, Proposal Manager at Siemens Energy said, “Modelon Impact being cloud-based makes it very easy for us to access the platform and our projects. This helps foster collaboration within our team and streamline our design process.”

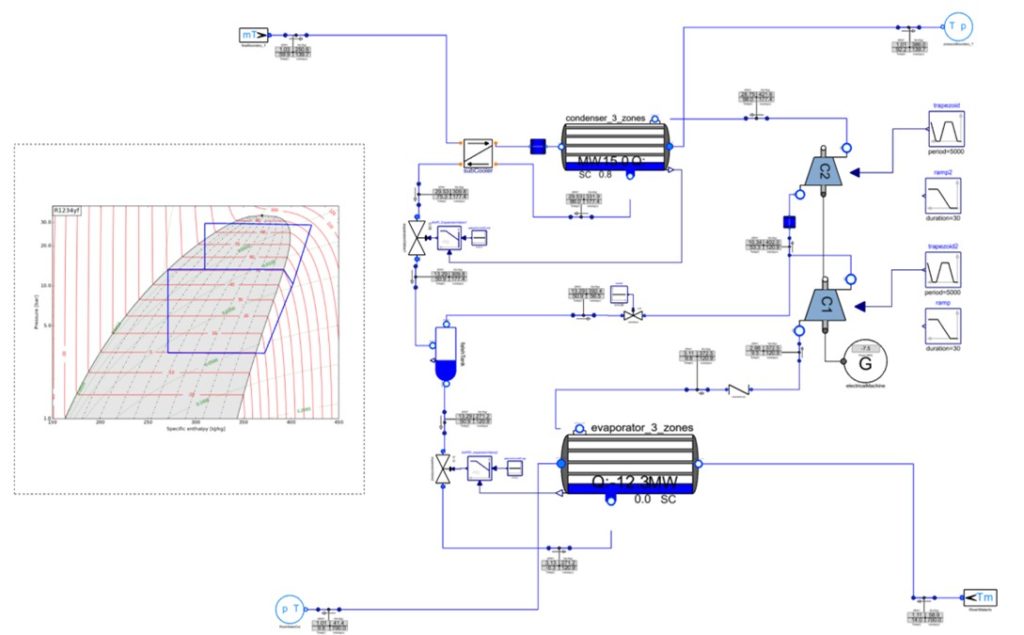

Additionally, Siemens Energy needed fully equipped and validated libraries to build the complete heat pump accurately while reducing time to market, development costs, and improving product quality. Using the Modelica-based libraries within Modelon Impact, Siemens Energy developed a detailed transient heat pump model, shown below in Figure 2.

Besides replicating the behavior of the existing system, the detailed heat pump model allowed Siemens Energy to alter design parameters and system structure: including heat exchangers, valves, compressors, and control loops. In addition, the flexibility of Modelon’s libraries allowed investigation of different working fluids inside the system – which is a prerequisite for following environmental trends to reduce global warming potential (GWP), while maintaining high efficiency.

After the detailed heat pump model was created, engineers at Siemens Energy integrated it into an example district heating network system, one of hundreds of pre-built system models that come standard in Modelon Impact, all while coupling the compressor power supply to a readily available renewable energy producer model. In this case, a wind park is shown below in Figure 3.

Result

Integrating the heat pump system model into a district heating network system via Modelon Impact allowed Siemens Energy to understand the flows and capacities of its heat pumps in a more detailed manner. “Working with Modelon Impact has been a seamless process. I easily followed the instructions, logged in, and simulated the heat pump model without any problems” says Anna Sjunesson, Dynamic Simulation Expert at Siemens Energy. The resulting model enabled analyses of thermodynamic states such as temperatures, flows, and pressures at all consumers as well as the conventional cogeneration plant that feeds the system. For the heat pump design and optimization, the integration of a high-fidelity district heating system model resulted in a significantly more accurate capture of system interactions compared to previous development approaches. This enables a streamlined workflow that results in an optimal technology design within not just a test environment, but in its actual environment.

To allow model access for distributed engineering teams, Modelon has provided access to the cloud server running Modelon Impact and the heat pump models for the global team of Siemens Energy engineers. John Svensson, Thermodynamics Expert at Siemens Energy says, “From initial testing, I’ve determined that the heat pump model in Modelon Impact works efficiently and is a useful resource for our team. In the future, we hope to continue using this model to easily modify and optimize parameters for our design process.”

Siemens Energy has chosen to use Modelon Impact as its tool for future heat pump development. Modelon Impact’s model-based simulation software enables Siemens Energy to integrate its well-established, efficient, and reliable heat pump systems into technically complex environments. Thus, enabling more sustainable solutions for residential and industrial heat supply or thermal energy storage.