Multi-body Vehicle Dynamics: Efficient Suspension Design in Modelon Impact

This blog highlights the capabilities of Modelon’s Vehicle Dynamics Library, integrated and available in Modelon Impact, to efficiently model and simulate suspension systems. Modelon Impact’s steady-state solver and multi-execution capabilities make it possible to achieve steady-state analysis with speed and precision for multibody vehicle dynamics. Then, deploy your suspension simulation and analysis into a web app through Modelon’s open APIs.

Part 2 of this blog series, Chassis Design and Analysis, focuses on the capabilities that make it possible to achieve steady-state analysis for multi-body vehicle dynamics in Modelon Impact.

Suspension Design Enabled by Vehicle Dynamics Library

Modelon Impact comes equipped with a comprehensive set of multi-physics libraries that are built-in and easily accessible. The platform allows you simply drag and drop pre-built models and components to the canvas – this includes components and models from Modelon’s Vehicle Dynamics Library. Launched in 2004, Vehicle Dynamics Library has been utilized extensively in automotive applications ranging from passenger cars to motorsports and heavy-duty transport.

The library covers all main subsystems of a typical multibody vehicle including suspensions, wheels, powertrains, and brakes. Built on the multi-physics capabilities of Modelica, it is simple to add components from additional libraries including the Modelon’s Electrification Library, Hydraulics Library, and Pneumatics Library.

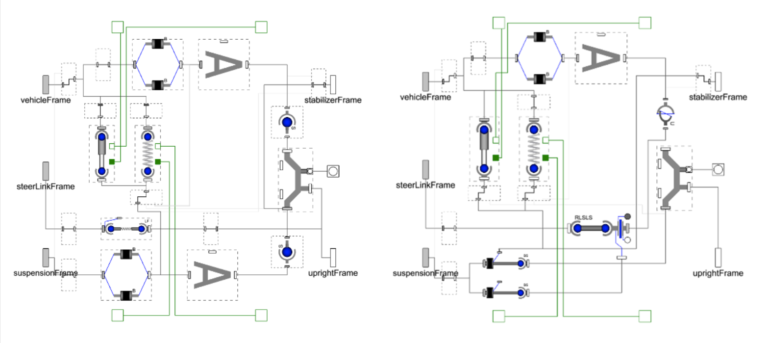

When it comes to suspension modeling, Vehicle Dynamics Library offers an extensive range of suspension topologies. This includes traditional MacPherson and double wishbone variants as well as more modern multilink variants for passenger cars. There are also models of dependent suspensions like twist-beam rear suspensions and a range of axle options for heavy trucks.

Each suspension template contains replaceable mounts and switch parts so they can easily be reconfigured depending on where suspension elements like stabilizers, springs, and dampers are attached.

Suspension Design Analysis in Modelon Impact

With the steady-state simulation capabilities of Modelon Impact, we can now expand the types of analyses we do on suspensions using Modelon’s Vehicle Dynamics Library. The suspension model is constrained in a rig with wheel travel and steering inputs as boundary conditions. We then solve for steady-state, meaning all state derivatives are zero, thus excluding any effects of damping, both in the dampers themselves as well as in suspension bushings. It is usually more efficient to solve for steady-state in each position instead of dynamically sweeping the suspension through wheel travel or steering because the solver doesn’t have to deal with dynamics in stiff bushings. This approach also provides better accuracy because the dynamic effects do not affect the result.

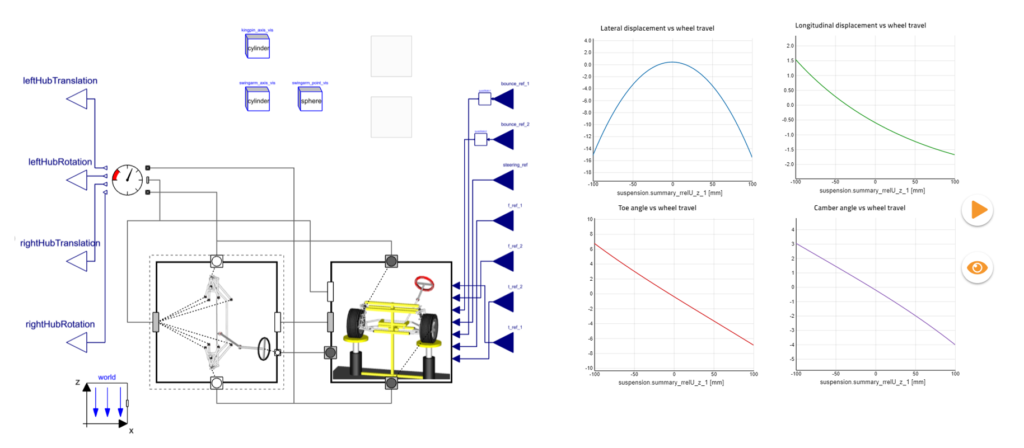

For a given suspension model, we can sweep through a set of wheel travel positions, solving for steady-state in each point, and extract the hub position and orientation. Below is the output of a parallel wheel travel analysis +/- 100 mm of an example fourlink suspension from Vehicle Dynamics Library.

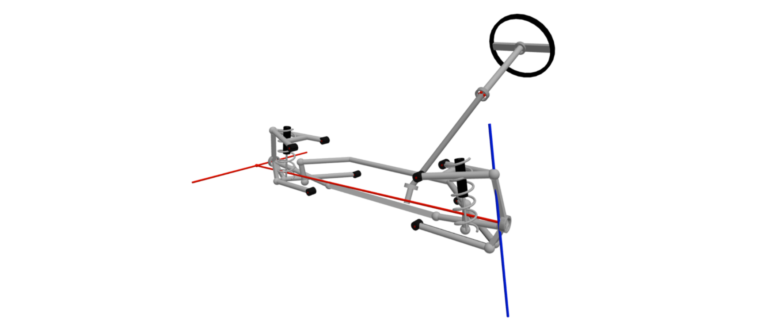

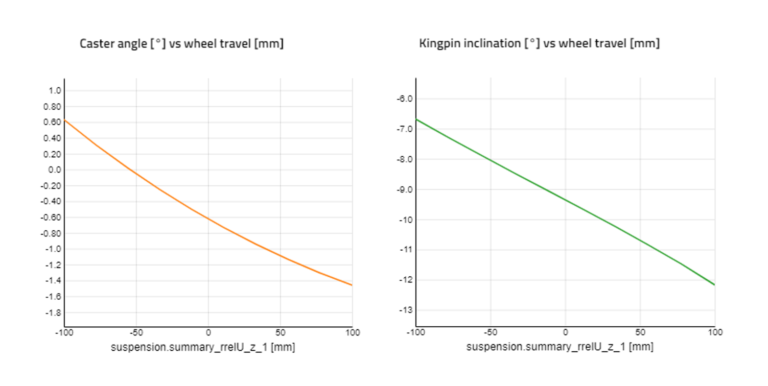

By adding multiple solution points around the analyzed position and using finite differences, we can also extract gradients to determine suspension characteristics such as bump steer and camber gain, meaning how toe and camber angle changes with wheel travel. Furthermore, we can use gradients with respect to steering and wheel travel to determine the instantaneous kingpin axis and the swing arms of the suspension for multibody vehicle dynamics. Once the kingpin axis and the swing arms of the suspension have been determined, the kinematic roll center of the suspension can also be calculated.

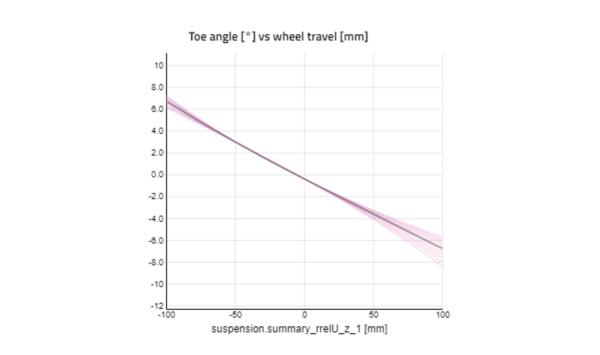

By using Modelon Impact’s multi-execution capabilities, engineers can set up parameter sweeps and repeat the analysis for each parameterization to evaluate how changes in suspension design will affect the behavior of multibody vehicle dynamics. Figure 1 shows toe angle w.r.t. wheel travel when adjusting the outer steer link joint +/- 50mm in the lateral direction.

Suspension Analysis Deployment to Web Apps

One of the key benefits of using Modelon Impact is the possibility to deploy analyses like these to a wider audience in an organization. Users of web applications may not be experts in suspension modeling but may still be interested in the outputs of such analysis. Suspension designers running CAD software could use this to quickly check the effects of different design choices for multibody vehicle dynamics.

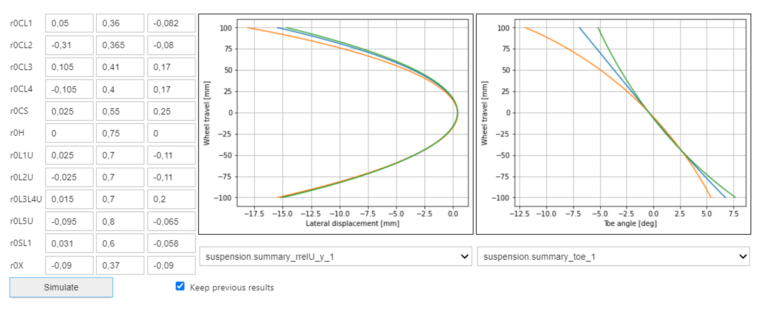

In Figure 2, we use the Impact Python Client in a Jupyter Notebook to create a GUI where a user can change suspension hard-points and run the analysis to see the effects.

A colleague who is proficient in Python and Jupyter Notebooks could of course create their own scripts and notebooks to run the analysis they need.

Conclusion

Modelon’s Vehicle Dynamics Library is even more powerful with the addition of steady-state simulations, multi-execution, and deployment offered with Modelon Impact. Analyses for a multibody vehicle are quicker and more accurate when done using the steady-state solver, multi-execution allows more parameterizations to be explored and deployment enables a wider audience to access to the answers they need.