Energy System Simulation Solutions

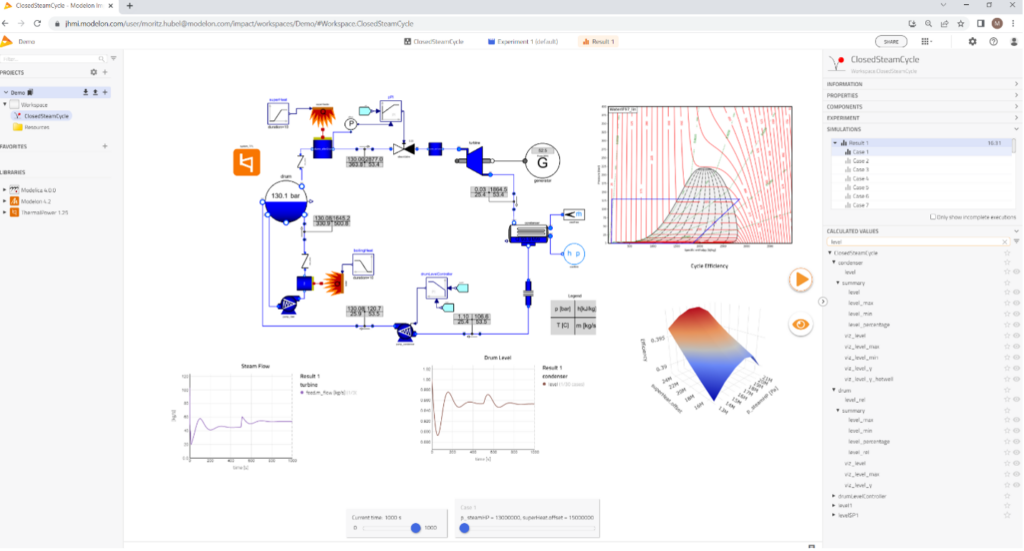

Modelon’s cloud-native platform, Modelon Impact, enables accurate physical modeling and simulation for energy systems and sub-systems.

Home » Industries » Energy and Power System Simulation Solutions

Modelon’s cloud-native platform, Modelon Impact, enables accurate physical modeling and simulation for energy systems and sub-systems.

Meet Modelon Impact – a cloud platform for designing, simulating, and analyzing physical systems. Our leading energy simulation experts have equipped Modelon Impact with everything your team needs to perform accurate and actionable physical modeling and simulation for a wide range of energy applications.

System simulation elevates engineering teams to new levels of productivity and innovation. Be at the forefront of designing cutting-edge energy systems with Modelon Impact.

Make better decisions about energy system architectures with quick and accurate simulation results.

Simulate power plant performance integrated with renewable energy sources and customizable performance parameters.

Build virtual copies of existing energy systems to retrofit your technology with the latest components and methods.

Seamlessly work with internal and external teams on the cloud to streamline the engineering design process.

The abstraction level of our first-principle-based physical allows us to accurately calculate & predict the transient and steady-state process behavior in on- and off-design conditions. Ranging from finding the best geometry of a heat exchanger to be integrated into a power plant for maximum efficiency or identifying the optimal size and operation schedule for a battery storage in an integrated energy system considering operational and capital expense.

The proven accuracy of our validated component models allows to support development processes from an early stage, even before prototypes and measurement data are available, setting our solutions apart from purely data-based approaches.

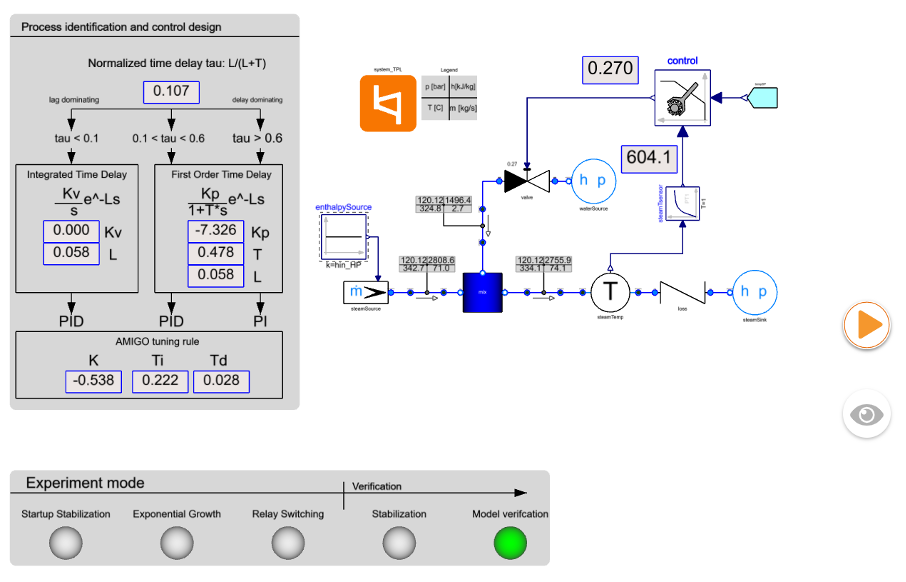

Develop new concepts to maximize the performance of transient process systems, including linear and non-linear model predictive control strategies, optimal control, or AI-based controllers. Use validated process models to tune the parameters of conventional PID controllers, perform stability analysis, and identify operation limits. Verify control concepts and parameters in a virtual environment to reduce risky field testing, shorten commissioning times and improve reliability and performance.

Besides control testing, human-in-the-loop applications of process and control models allow operator training.

Our models allow access to all the process variables, even those that can hardly be measured. Integrating them with live inputs, e.g., from fuel supply measurements, ambient conditions, operator inputs, or any measurement signal, a virtual representation (Digital Twin) can monitor component failures and inefficiencies. Based on this, countermeasures can be taken quickly, resulting in cost-savings and improved reliability & safety.

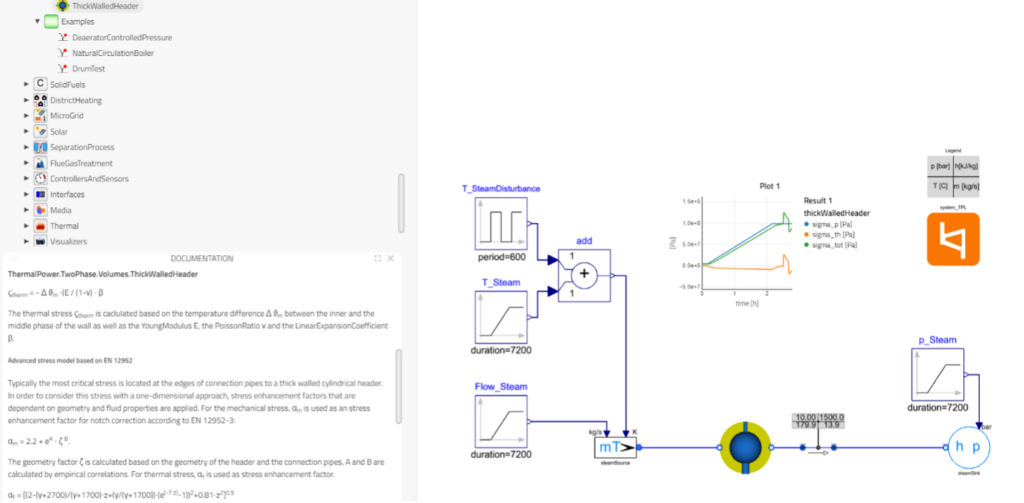

Our thermal conduction models for critical components include thermal and mechanical stress calculations according to EN12952 guidelines. Based on this, plant lifetime can be monitored – offline and online using the Modelon Impact API, industry-standard communication protocols (OPC, MQTT), or model export into more than 100 different execution environments using FMI technology.

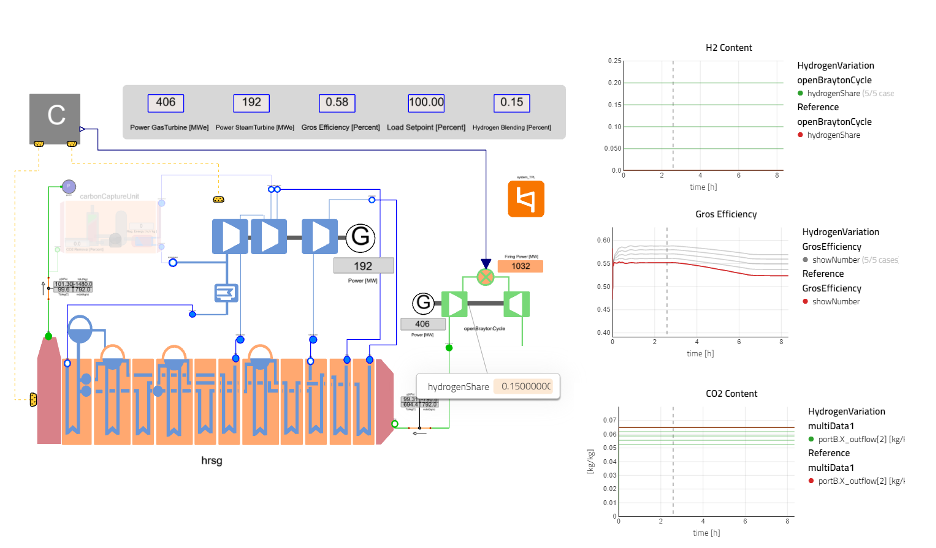

Risk-free and cost-efficient testing of new components inside the actual system. The toolchain allows the quick implementation of a physical model of any existing system, even a complex energy system, e.g., a process or power plant with several hundred individual components. This is done by dragging, dropping, connecting, and parameterizing each component. Using the validated system models as a virtual test bench, any process retrofit can be tested in a realistic environment to identify and verify the optimal choices. This allows substantial risk mitigation and shortening of commissioning times for plant retrofits, updates, and extensions, e.g., integration of alternative fuels such as hydrogen into existing plants.

Hydropower, Solar, Fuel Cell, Wind Power, Inverter, and Control Design

Carbon Capture, Flexibility Analysis, Fatigue Life Assessment, Control, and Plant Design

Microgrid Design, Energy Management, Transmission & Distribution, Transient and Fault Analysis

Cogeneration Plant, Heating & Cooling Networks, Distributed Production, Heat Pumps, and Chillers

Thermal and Electric Storage, Hydrogen Production and Storage, Integrated Energy Systems

Hear from Mert Gevechi, Principal Controls Engineer at Malta Inc. on how Modelon helps Malta supply power grids with electricity from renewable energy storage systems.

Choosing Modelon Impact as our platform for dynamic system simulation was an important strategic decision. We are developing critical sustainable state-of-the-art energy systems to meet growing global demand and decarbonization targets. Modelon’s established authority and credibility in energy systems modeling and their pace for developing a cloud-based platform [Modelon Impact] aligned with our roadmap and mission – to bring advanced thermal energy and storage systems to a global market with speed and assurance. The self-critical and agile continuous improvement mindset of the Modelon team matches with MAN ES’ approach in novel system solutions development. We trust that Modelon and Modelon Impact will help us change the world of power production for a more sustainable future.

Emmanuel Jacquemoud

Technical Project Lead ETES, MAN Energy Solutions

You’ve got ambitious projects that need the right expertise. We’ve got the experience to steer you in the right direction. From our world-class modeling experts to instructor-led and self-guided training, we’re here to guide you to success.

Always at hand to help our customers be at their most productive.

Deep industry knowledge and specialization to help with the most niche applications.

Get in touch today to see how Modelon Impact can help you with your system simulation and product design journey.