Integrating Carbon Capture and Sequestration (CCS) with Natural Gas Combined Cycle Power Plants

Carbon dioxide (CO2) is one of the main greenhouse gas (GHG) emissions driving global climate change. Both coal-fired power plants and natural gas combined cycle power plants (NGCC) are significant sources of carbon dioxide emissions, however, the amount of emissions varies between the two types of power plants.

Coal-Fired Power Plants

Coal-fired power plants are one of the largest sources of carbon dioxide emissions worldwide. They generate electricity by burning coal to create steam. This steam is then used to drive turbines and generators, resulting in the production of electricity. These facilities are commonly used as a source of energy due to the abundant supply of coal in many regions of the world. However, the environmental impact of coal-fired power generation, such as greenhouse gas emissions, has led to the development and adoption of alternative sources of energy like natural gas combined cycle power plants.

Natural Gas Combined Cycle (NGCC) Power Plants

Natural gas combined cycle (NGCC) power plants are widely adopted for power generation in North America and Europe because they enhance natural gas fuel efficiency. While NGCC power plants emit less carbon dioxide than coal-fired power plants, they still contribute significantly to carbon dioxide emissions. This method involves a gas turbine generator producing electricity and recycling waste heat to create steam, which then generates additional electricity via a steam turbine. NGCC power plants have moderate capital costs and short construction time.

The main difference results from the fact that in a coal-fired unit, the fuel consists of up to 100% carbon (C) allowing none other than CO2 for conversion. Natural gas consists of mostly Methane (CH4), so only a very small fraction (1 out of 5 atoms) of the fuel can convert into CO2. Each C-atom carries 4 Hydrogen atoms which combustion leads to no CO2, only water. This is the main driver of NGCC power plants being more carbon friendly.

The efficiency of each power plant is also a differentiator. NGCC power plants combining the Brayton cycle and Rankine cycle can have efficiencies beyond 63%. The coal-fired power plants relying only on the Rankine cycle have an efficiency of around 37% and the highest efficiency below 50% [1]. In other words, less carbon dioxide (CO2) is emitted for generating the same amount of electricity power by a NGCC power plant than by a coal-fired power plant.

And lastly, although the share of renewable energy sources is increasing in the energy industry, coal, and natural gas will remain dominant for power generation now and in the near future.

Reducing CO2 Emissions with Carbon Capture and Sequestration (CCS)

The process of capturing and storing atmospheric carbon dioxide is known as carbon capture and sequestration (CCS). It is a promising approach to reduce global emissions of greenhouse gas (GHG) into the atmosphere, and thus curb the long-term effects of climate change. This is because it can be easily integrated into both new and existing power plants with minimal modifications. There are generally three types of carbon capture and sequestration technologies (CCS):

- Post-combustion capture uses a solvent to capture CO2 for the flue gas of power plants. The solvent is then regenerated.

- Oxy-fuel combustion is when fossil fuel is combusted with nearly pure oxygen and recycled flue gas or CO2 and steam to produce a flue gas consisting of CO2 and water.

- Pre-combustion capture occurs when a fuel is reacted with air or oxygen to produce a fuel that contains CO and H2. This is then reacted with the steam in a shift reactor to produce a mixture of CO2 and H2.

Specifically, the highly prospective technology is post-combustion CO2 capture using chemical absorption with monoethanolamine (MEA) as solvent. This is because it can assess transient plant power performance and operate at room temperature and atmospheric pressure. It has been proven that the integration of CCS and natural gas power generation systems is technically feasible in the energy and industrial sectors. The combination of natural gas combined cycle technology and post-combustion carbon capture is a cost-effective solution for reducing CO2 emissions.

Challenges Engineers Face with Combined CCS and NGCC Power Plants

Integrating NGCC plants with post-combustion carbon capture is a task that still faces several challenges.

- It requires modified engineering designs for post-combustion carbon capture and high capital cost of the required equipment.

- Engineers and researchers must face the lack of dynamic operational data of the post-combustion CO2 capture integrated with commercial-scale natural gas combined cycle power plants. Therefore, the study on the transient performance of NCCC power plants with post-combustion carbon capture is limited.

The efficiency of power plants is greatly affected by the design of their control system, particularly for natural gas combined cycle (NGCC) power plants that use CCS technology. The use of CCS in a NGCC power plant can reduce its efficiency. To optimize a power plant’s performance, engineers need to perform a dynamic analysis of the interactions between the control system and CCS. This is where modeling and system simulation technologies can help engineers to identify inefficiencies and improve the integration of NGCC power plants with CCS.

System Simulation Capabilities for Carbon Capture

Modelon Impact provides a dynamic simulation to assess the transient performance of NCCC power plants with post-combustion carbon capture during load changes. The carbon capture and sequestration (CCS) unit in the system model can be replaceable, thus allowing analysis of the dynamic interaction between NGCC plants and different post-combustion carbon capture units. Carbon dioxide absorption with MEA is one of the possible types of carbon capture units that can be used in NGCC power plants. It is used by large European energy companies and universities. The CO2 absorption unit’s new feature of one-factor scaling enables the unit model to be compatible with relevant power plants operating at loads from 20 MW to 800 MW. Modelon Impact also offers the capabilities to analyze the control structures on the NGCC plants with post-combustion carbon capture and the efficiency loss of the post-combustion carbon capture.

NGCC Power Plant with Carbon Capture Use Case

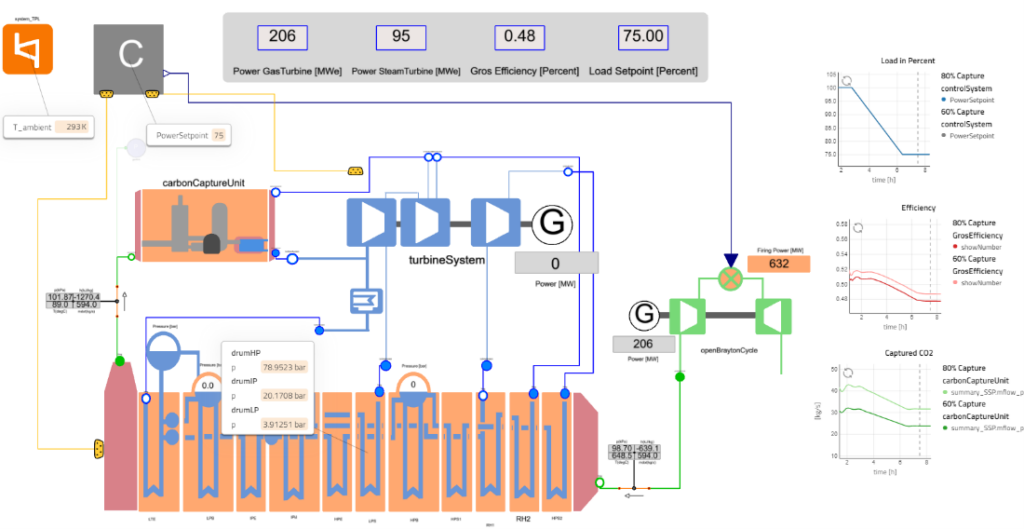

Modelon Impact‘s integrated Thermal Power Library presents a natural gas combined cycle power plant model with a three-pressure reheat system and an optional post-combustion carbon dioxide capture, as shown in Figure 1.

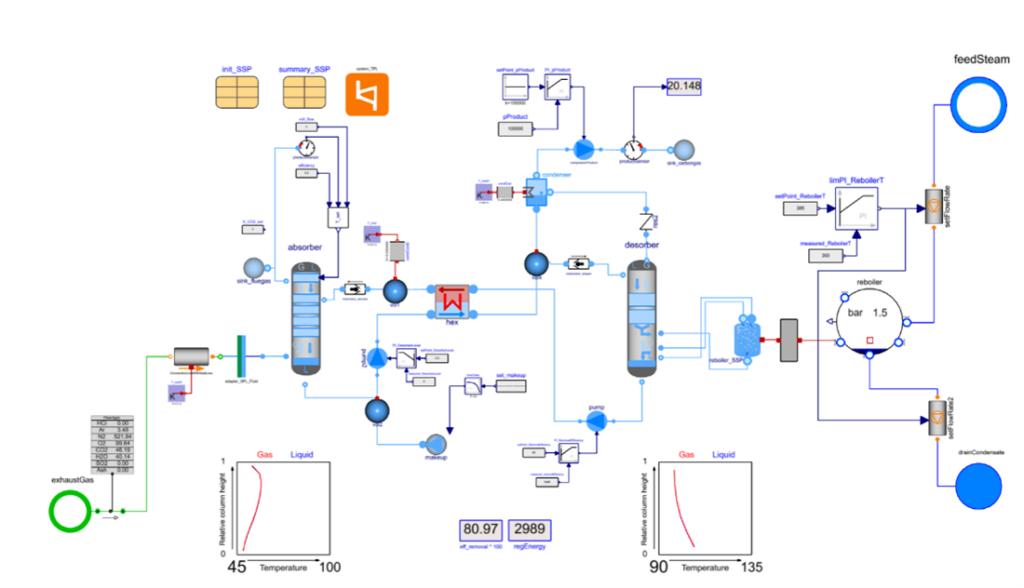

The model includes one steam cycle consisting of a heat recovery steam generator (HRSG), turbine, and one Brayton cycle for power generation using natural gas. The optional post-combustion CO2 capture unit is connected to the HRSGs furnace. Steam is extracted from the turbine to feed the reboiler of the scalable carbon capture unit as shown below in Figure 2.

The control structures are implemented for the units of the steam cycle, HRSG, and carbon capture and sequestration (CCS). The model of the CO2 chemical absorption unit including one absorber and one desorber has been validated [2,3], and it is scaled up to be compatible with the 400 MW NGCC power plant. The presented scenarios include two operating points with a load change and two variants of CO2 removal setpoints. First, the system is operating at a steady state with 100% load and 80% CO2 absorption. A load change to a low load (75%) is simulated to verify the implemented control system works as expected. The scenario is repeated with a 60% absorption setpoint to verify the effects on the plant’s overall efficiency.

Modeling and Simulating Combined Cycle Plants With Modelon Impact

Exploring the role of NGCC power plants with carbon capture, utilization, and sequestration can lead to reducing carbon emissions and mitigating climate change. Dynamic analysis is critical for developing and designing the integration of NGCC power plants and CCS / CCUS. Modelon Impact is a powerful dynamic tool that can offer more possibilities and capabilities for the integration of these technologies, including not only the development of system-level simulation and design of control strategy, but also the assessments of transient load changes on NGCC plants, the carbon capture and sequestration implementation, efficiency loss, control structures, the utilization of scalable unit models, and the system-level optimizations.

At the same time, Hydrogen blending in the gas turbine can be investigated as presented earlier. Reach out to our experts to learn how you can utilize system simulation for carbon capture systems!

References

[1] Energy Information Agency – International Energy Outlook 2022 (https://www.eia.gov/outlooks/aeo/pdf/AEO2022_ReleasePresentation.pdf)

[2] Montañés, Rubén M., et al. “Demonstrating load-change transient performance of a commercial-scale natural gas combined cycle power plant with post-combustion CO2 capture.” International Journal of Greenhouse Gas Control 63 (2017): 158-174.

[3] Montañés, Rubén Mocholí. “Transient performance of combined cycle power plant with absorption-based post-combustion CO2 capture: dynamic simulations and pilot plant testing.” (2018).