Design and Simulate Santa’s Sleigh With System Simulation

Preparing for the Big Night

With the holiday season approaching, Santa has been preparing to deliver gifts. This year, however, he wants the North Pole to be more energy efficient by creating a new sleigh with improved features. Santa turns to Modelon and Modelon Impact for these updates:

- Optimize the sleigh’s energy efficiency

- Charge Santa’s electric sleigh to lower his environmental footprint

- Minimize the operating cost of Santa’s charging station

- Improve the sleigh’s vehicle dynamics

- Conduct dynamic maneuvering stability and a steady state analysis of Santa’s sleigh

- Successfully land and generate electricity that assists the reindeer in flying the sleigh

- Land Santa’s heavy sleigh by simulating the angle of attack

- Add a cryogenic hydrogen tank to the sleigh to supply a fuel cell

- Heat the sleigh

- Develop a thermal management system to keep Santa warm, protect components from aging, and maintain adequate operating ranges for the new batteries

See how Santa uses Modelon Impact to prepare for the holidays and create his super sleigh!

Energy Efficiency of Santa’s Sleigh

Santa decided to do an energy analysis from last year and was shocked by what he found. When delivering gifts, Santa had consumed a surplus of electric energy from nonrenewable resources to fuel his electric sleigh and unknowingly contributed 0.3 tons/day of CO2 into the atmosphere. This is a big problem when the entire world is talking about reducing the effects of climate change and carbon neutrality! So, this year he decided to strategize his travel in an eco-friendly manner. Santa has two things in mind:

- Charge his electric sleigh with minimum environmental impact

- Minimize the operating cost of his charging station

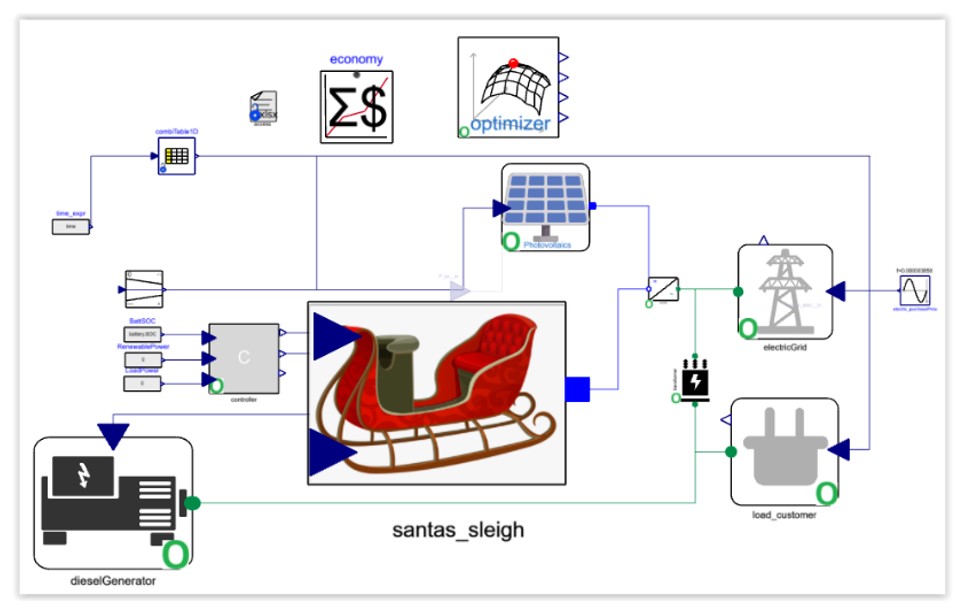

To address these problems, Santa begins by using his model-based design skills with his favorite simulation tool – Modelon Impact! Santa’s charging station represents a microgrid or local grid system where the electricity demands are met by solar power, batteries, a diesel generator, an electric grid, and a storage system in Santa’s sleigh. Like batteries, Santa’s energy storage system also has the potential to import and export power, as shown in Figure 1 below.

These energy sources come with varying operating prices, weather dependence, and availability. The optimizer package in Modelon Impact addresses Santa’s challenge as it includes dynamic optimization functions which can set the operation of the charging station at a minimal cost within the emission along with other constraints.

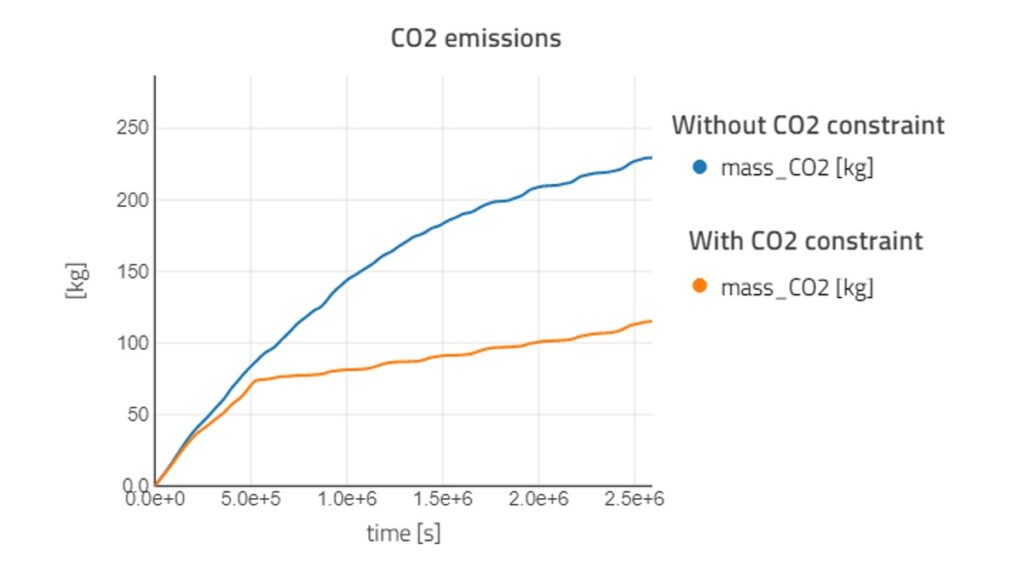

After parameterizing the microgrid model of his charging station, Santa sets the maximum CO2 emission constraint to less than 0.5 tons/day and runs the simulation with dynamic optimization to see the following result in Figure 2.

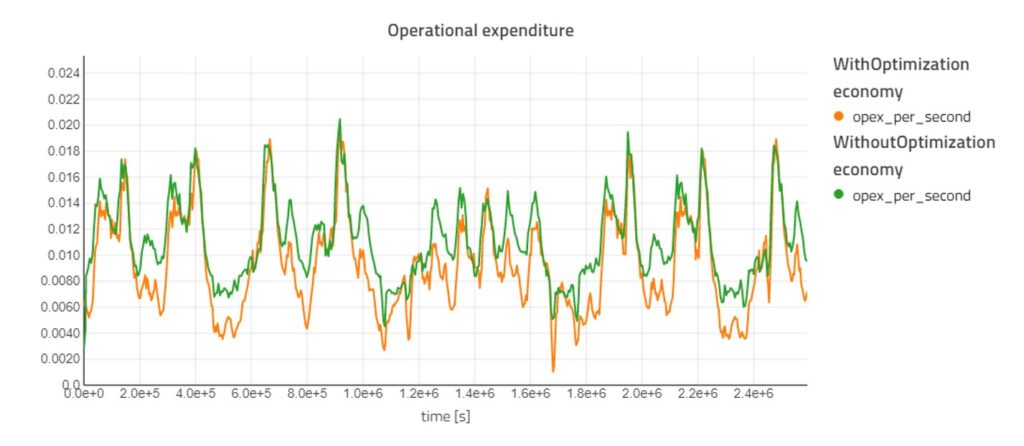

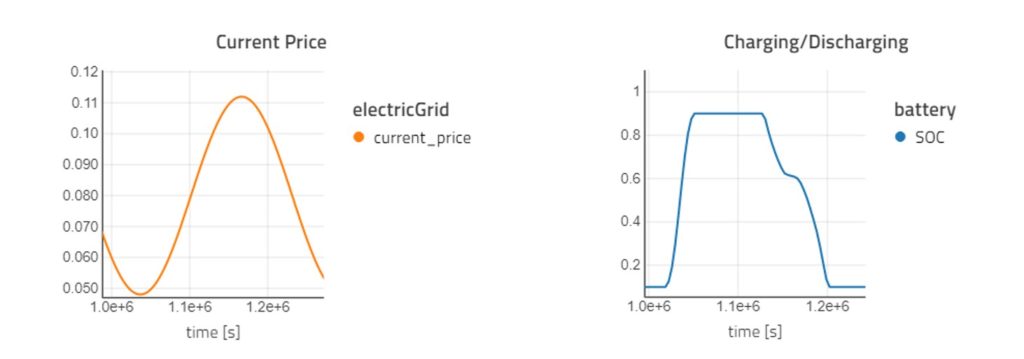

Santa is pleased to learn that the optimizer has reduced his plant’s operating costs by 12% to an average of 0.009 dollars/second, allowing him to use the battery storage to purchase more energy when the grid’s energy import price is low (surplus energy to charge the batteries) and sell them or meet load requirements when the price is high (discharging from batteries). This is shown below in Figures 3 and 4.

With the help of Modelon Impact, he is now able to identify the ideal combination of energy sources at a specific time for the efficient conduct of his charging station. Additionally, he has observed that not only can Modelon Impact be used to design optimal operation, but the sizing experiments included have the capability for the optimal design of components along with operation.

Now Santa plans on running these simulations year after year to scale down the energy sources that possess a higher carbon footprint.

Maneuvering Santa’s Sleigh

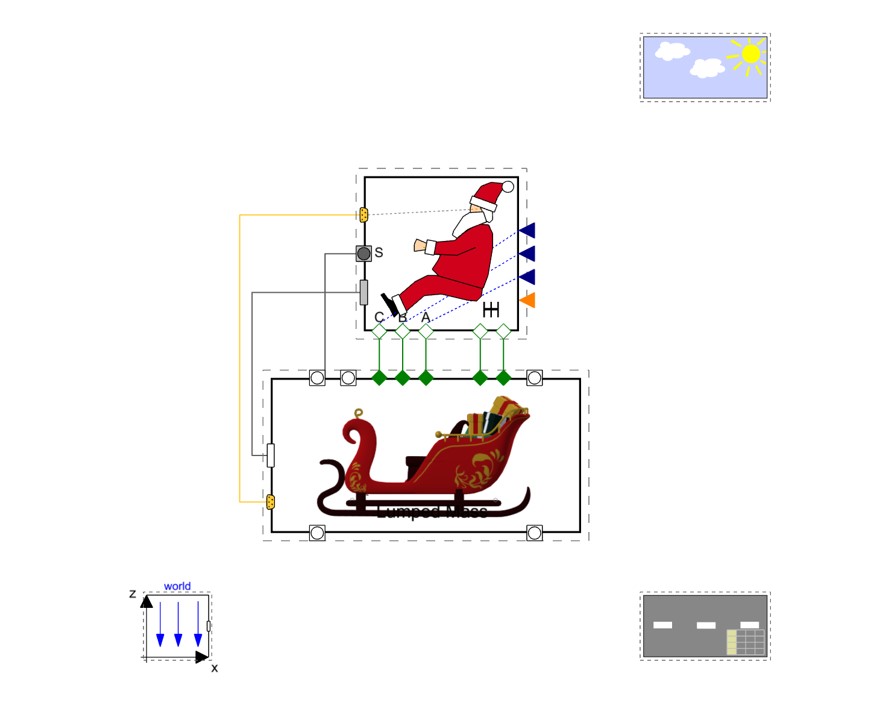

Not only do magic and reindeer fly Santa’s sleigh, but a bit of vehicle dynamics helps too! Santa’s vehicle dynamics challenge is that he must control and maneuver his sled which is fully loaded with packages for all the good girls and boys of the world. He must also account for maneuvering around trees, on rooftops with chimneys, and through tight areas on a wide range of surfaces. Santa decides that he needs to improve the dynamic capabilities of his sled for safety and package delivery efficiency. He turns to Modelon Impact to leverage modern model-based design methods to drive the design changes for the sled. The first step is to leverage existing templates to quickly build a multi-body model of the sleigh and test it under dynamic conditions as driven by Santa on a particular surface as shown in the figure below.

Santa runs the current sleigh design through a series of dynamic simulations to evaluate the performance under quick and tight turns. As shown in the animation below, the current sleigh cannot safely handle this maneuver without risking danger to Santa, his reindeer, and the precious cargo he carries.

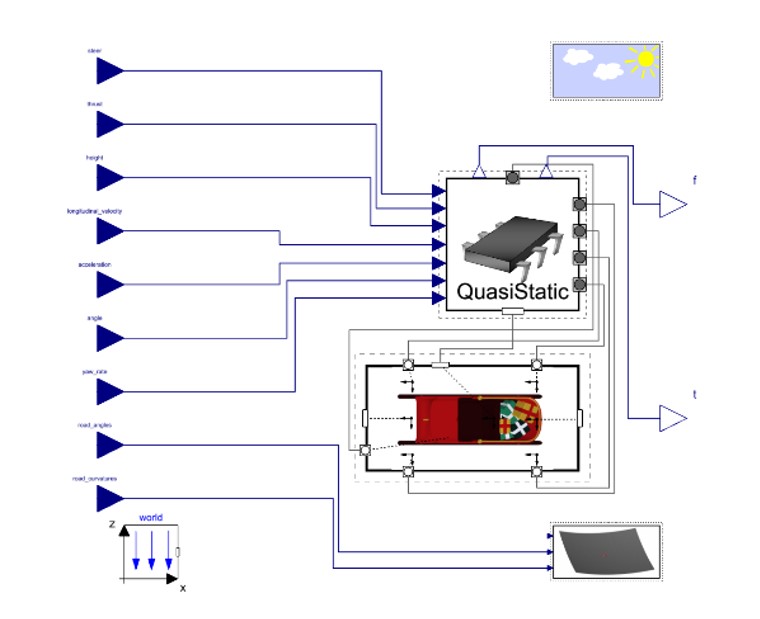

To optimize maneuverability and stability, Santa runs a series of steady-state simulations using Modelon Impact. The figure below shows the quasi-static cornering simulation used to optimize the sleigh skid geometry to deliver improved performance over a range of sleigh speeds, cornering angles, and surface conditions. The quasi-static experiment can accurately show Santa how properties like payload position, skid geometry, and control inputs can affect the performance envelope of the sleigh, as shown below in Figure 8. Animations of the sleigh contact forces with the ground provide graphical feedback of the improved cornering response.

Santa also analyzes the animations of the sleigh contact forces with the ground which provides graphical feedback on the improved cornering response. All of these features are available in Modelon Impact!

With an improved sleigh design, Santa and his team of reindeer can safely navigate his global route at even greater speeds!

Landing Santa’s Sleigh

Santa’s sleigh is getting heavier each year. As he loads up more presents, his sleigh’s angle of attack becomes steeper and steeper, especially right before landing. This happens because the dynamic pressure under his sleigh is low, and this steeper angle is required to generate enough lift for his sleigh.

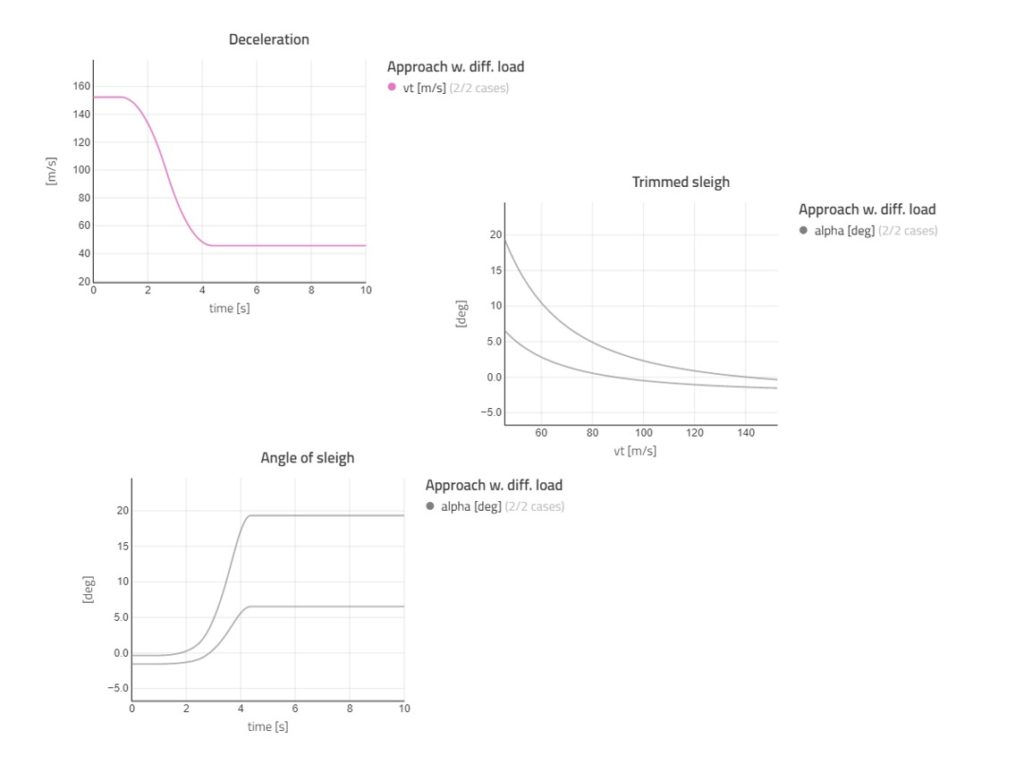

Santa uses Modelon Impact to model and discovers the matching results. As he approaches different homes, he would decelerate from 150 meters per second to just above 40 meters/per second within a couple of seconds. Normally, his angle of attack would peak just above 6 degrees. With the load of presents he must distribute this year, he needs about 20 degrees at low speed, which is very hard for him to control! This is shown in the figures below.

After seeing the results of the deceleration, trimmed sleigh, and angle of the sleigh in Modelon Impact, Santa decides he needs new ways to handle his important mission! In his model, he adds a small wing to the sleigh that creates more lift. However, the reindeer cannot handle the drag! So, he comes up with a cryogenic hydrogen tank design to add to the sleigh that supplies a fuel cell. He chooses from two designs, shown below in Figure 12 – either a spherical or cylindrical geometry on his winged sleigh. The cylindrical option leaves less legroom for him but balances the sleigh much better, so he decides to go with that one.

Figure 12: Two sleigh design options Santa models in Modelon Impact

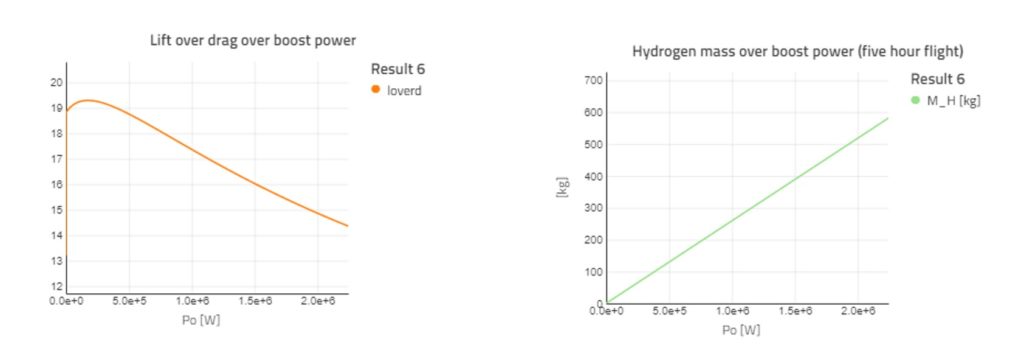

By modeling and simulating this, Santa can generate electricity for propellers that assist the reindeer. In figure 13, Santa computes that with 200 kW of boost power, the sleigh becomes aerodynamically very efficient (peak lift-over-drag value). Assuming he needs five hours to deliver gifts, his fuel cell will consume 50 kg of hydrogen.

Lastly, Santa needs to accommodate his 50 kg of liquid hydrogen in a tank with minimal mass using the spherical tank geometry.

Figure 14 shows the results when using evacuated aluminum foil and glass paper laminate at 8mm insulation thickness and 1.5mm titanium walls for the structure. Santa can accommodate his 50 kg of liquid hydrogen in a tank with minimal mass. Now he will manage to deliver all the presents his elves made to kids around the world!

Keeping Santa Warm

Santa decided to develop a thermal management system for his new sleigh to stay warm when he delivers gifts in cold, winter locations. Thermal management plays a key role not only for his comfort, but also to protect components from aging and maintain adequate operating ranges for the new batteries. Santa projects that the energy required for thermal management is in the range of 5-15% of the energy needed for propulsion. Thus, efficiency will have a big impact on the system.

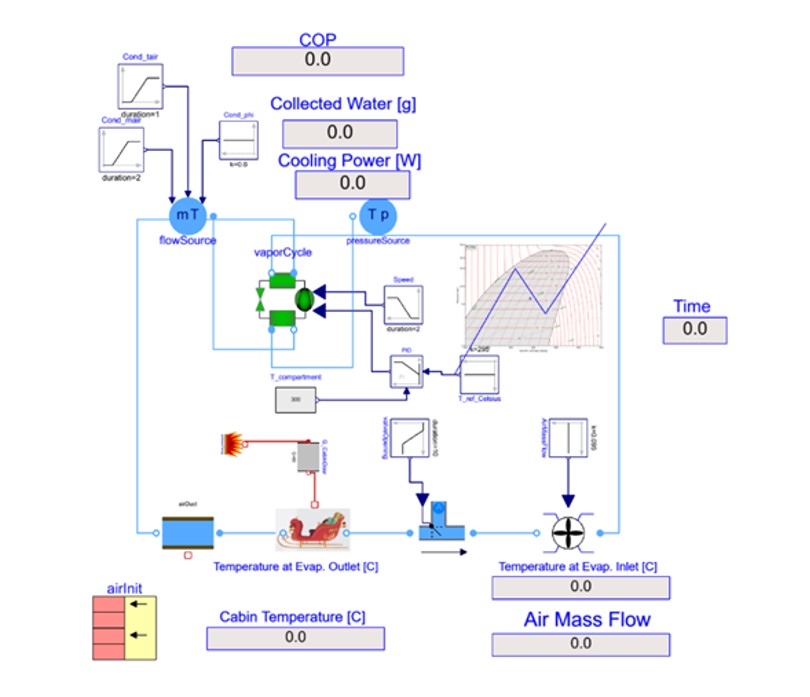

First, Santa needs to design the cabin. Initially, he uses detailed computational fluid dynamics (CFD) calculations to develop several sleigh design ideas – convertible roofs, solar roofs, and fixed roofs. He soon realizes it’s essential to evaluate these designs under the varying weather conditions of the travel. Santa turns to Modelon Impact where he can easily set up the vapor cycle with a cabin experiment, shown below in Figure 15.

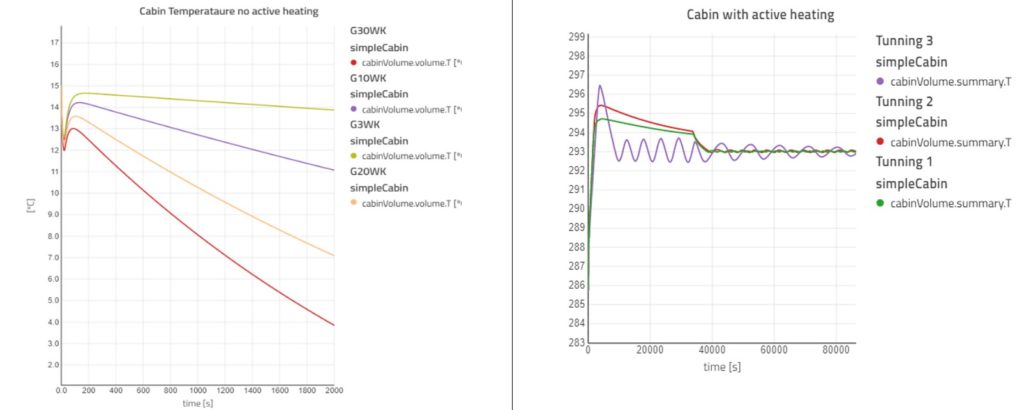

Once the CFD parameters for the cabin model were adapted, all is set to run dynamic experiments. First, Santa simulates the cabin without active heating and tested the performance of insulations with different thermal conductance (G) in Modelon Impact. Results like the one shown in Figure 16 (with no active heating) confirm that active heating is still necessary, hence Santa evaluates this option. One example of the results obtained while tuning the controls for active heating is shown in Figure 16 (with heating). This workflow is repeated for different design options, heating systems, and cooling systems.

Based on the vapor cycle models and active heating experiment results, Santa decides to go with the convertible roof option.

Modelon Impact successfully helped Santa connect his dynamic simulations within his traditional design process. He is ready to now deliver gifts at a comfortable temperature on his sleigh!

Ready to Take on the Big Night!

Ho, ho, ho! Santa is now ready to deliver gifts to all the good boys and girls around the world thanks to Modelon Impact! Just like Santa, modeling and simulation applies to many types of industries and domains. To learn more about the capabilities of Modelon Impact, please reach out to our expert team! And have a happy holiday season!