Using Modelon’s Hydraulics Library to Model Aircraft Hydraulic Circuit Architectures

*This blog was updated on February 22, 2019*

Today’s system engineering architectures are constantly evolving. Take hydraulic circuit design, for example. The concept of Electro Hydrostatic Actuation (EHA) has been adopted by aerospace technology leaders in recent years, leaving behind traditional hydraulic architectures like Servo Hydraulic Actuator (SHA) designs. While EHA can be lighter, more reliable, and reduce overall circuit power consumption, a large portion of the hydraulics industry still maintains SHA architectures or are in the process of transitioning from SHA to EHA architectures. Ultimately, the success of product development and analysis of alternatives depends on the ease with which a user can translate their design into a model.

Modelon’s Hydraulics Library is a comprehensive and versatile library that allows engineers to easily model both EHA and SHA by maintaining reusable and scalable components. Additionally, Modelon’s Hydraulics Library returns reliable simulation results so designers can gain maximum understanding about their system’s performance. In this blog, we’ll show just how easy it is to model both SHA and EHA architectures using the Modelon Hydraulics Library.

SHA vs. EHA: What’s the difference?

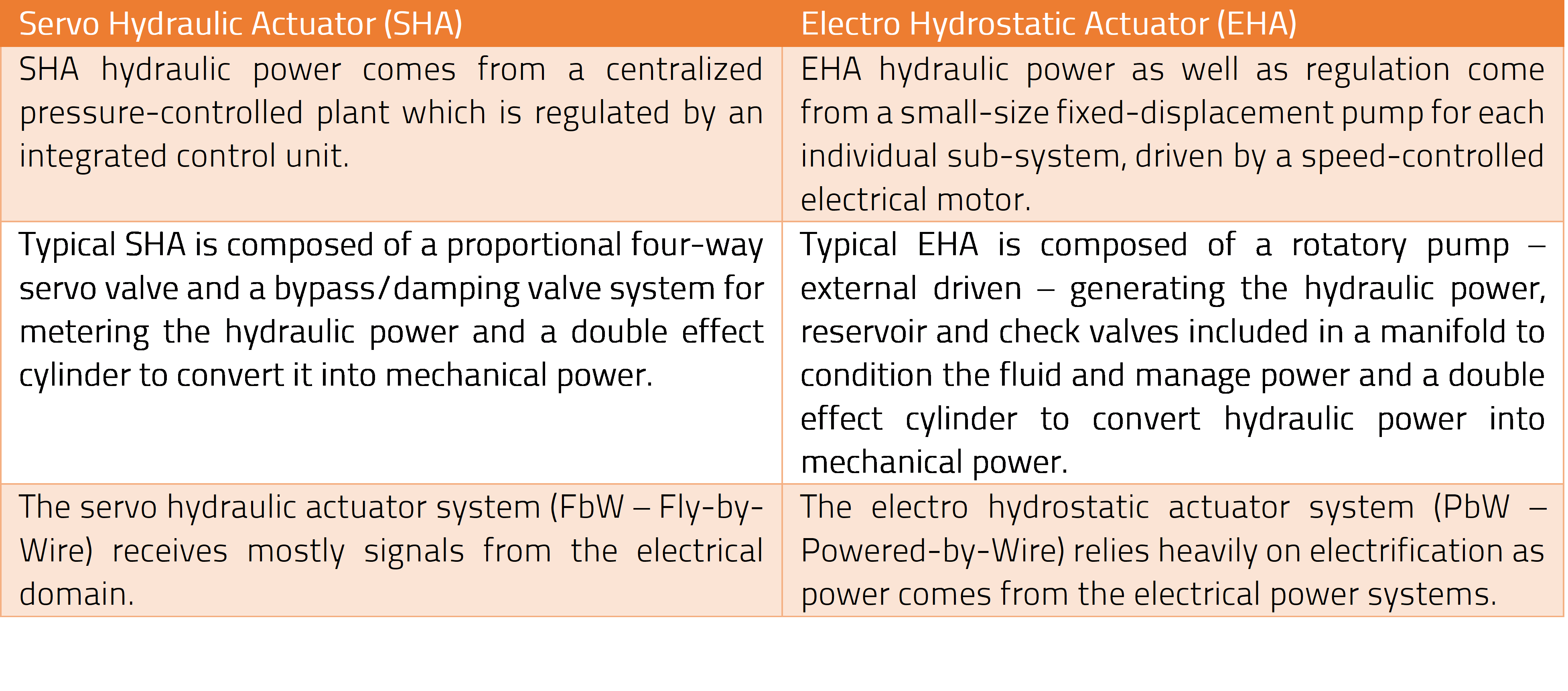

Before we get into modeling two different hydraulic circuit design architectures, let’s first understand how they compare. The basic difference between SHA and EHA architectures lies in the fact that SHA has a centralized pumping circuit that provides hydraulic power to many actuator systems. Figure 1 shows a deeper dive into the key differences between SHA and EHA.

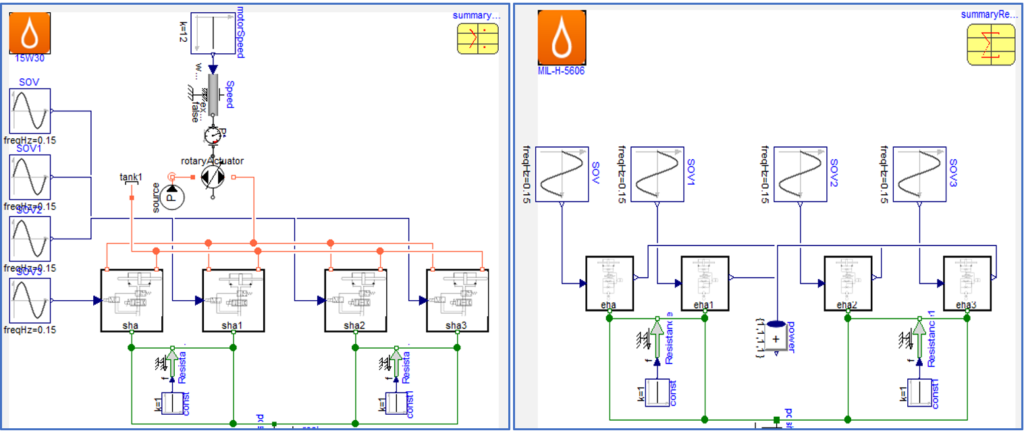

In SHA architecture, each pump feeds several actuators from multiple control surfaces of an aircraft (like elevator or aileron). In comparison, EHA architecture has a self-contained unit including pump and other valves for each actuator, with each actuator being used within a single control surface actuator system. The following Figure 2 shows a higher-level view of the models made for SHA (on the left) and EHA (on the right). In SHA, the common pump is available on the top-level hierarchy whereas, in EHA they are contained inside each actuator system (not visible at this level). Both models represent a system of four identical actuators that translates hydraulic power into translational motion. This motion will subsequently be converted using a suitable mechanism to actuate the control surfaces of an aircraft.

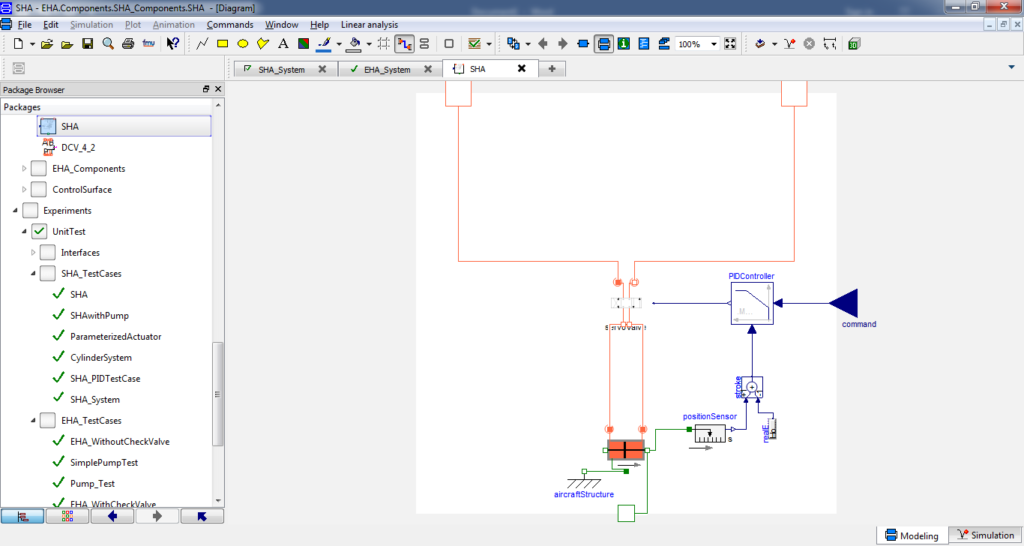

Modeling SHA Subsystems

Each actuator unit consists of a hydraulic jack (double acting cylinder), an electro-hydraulic servo valve (EHSV) and a controller for feeding commands to the servo valve. Both double acting cylinder and servo valves are available in the Modelon Hydraulics library by drag and drop. The servo valve is made with connections to two hydraulics ports of the subsystem that will receive fluid from the pump and return it to the tank. Additional elements like control valves can be added easily.

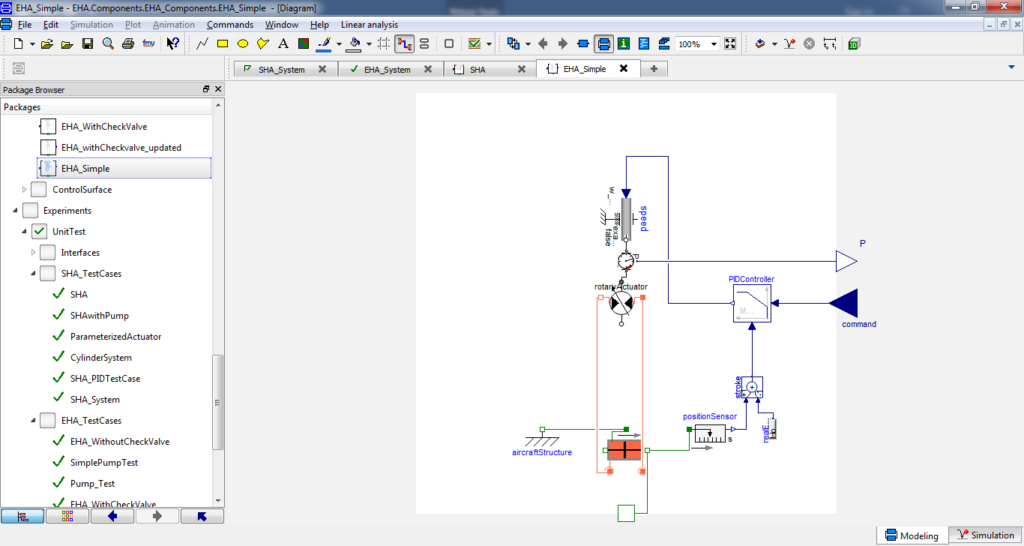

Modeling EHA Subsystems

Each actuator unit consists of a hydraulic jack (double acting cylinder), a bi-directional displacement pump and a controller for feeding commands to the pump in terms of speed. Both double acting cylinder and pump are available in the Modelon Hydraulics library by drag and drop. The hydraulic jack is positioned by varying the direction of rotation of the positive displacement pump.

Advantages of Hydraulics Library

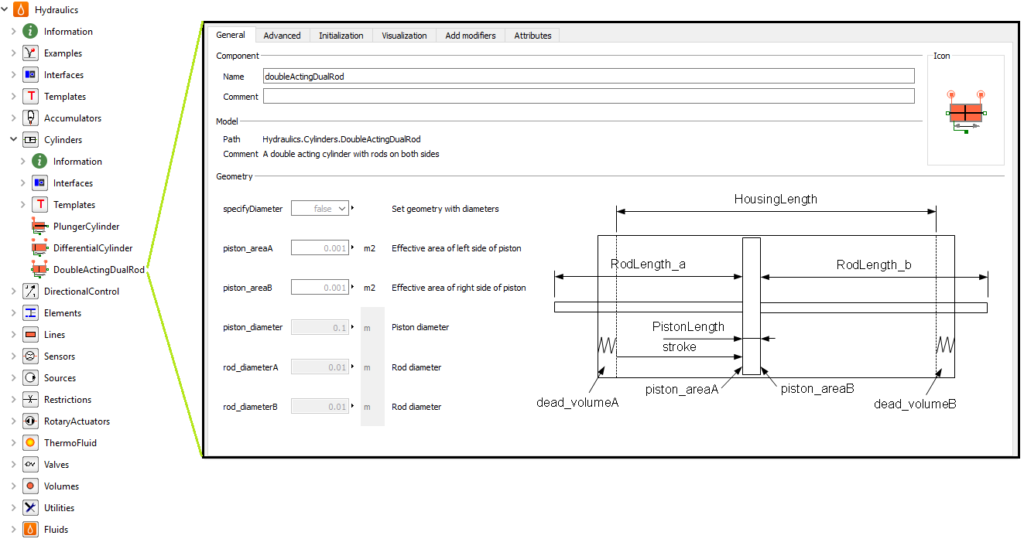

Modelon Hydraulic library has a plethora of components which are suitable for many engineering system architectures. Figure 5 below shows the Hydraulic library structure (on the left) with a wide range of components, packaged deliberately for easy understanding and usage. As shown in Figure 5 (on the right), parameters are well organized and are given additional details which makes the parameterization of the components easier for users. Modelon’s Hydraulics Library also includes features that enable users to have non-thermal and thermal hydraulics in the same framework.

Interested in learning more about the capabilities of the Modelon Hydraulics Library? Visit our product webpage to learn about the included components and applications of the library. Additionally, check out our other libraries, like the Electrification Library, on our Modelon Library Suite page.

If you’re unsure how the Modelon Hydraulics Library, or any other complimentary Modelon libraries, can meet your modeling and simulation needs, fill out the form below to talk to an expert.