Enhancing HVAC System Simulation and Operational Tuning for Takenaka Corporation

Summary

Takenaka Corporation is one of the largest engineering contractors in Japan, providing architectural, engineering, and consulting services. Takenaka Corporation’s Technical Research Institute is dedicated to optimizing building design and controls that support ZEB (Net Zero Energy Buildings). Faced with the challenge of optimizing HVAC system performance both at design and operational stages, Takenaka partnered with Modelon to leverage system simulation, enabling coupled analysis with EnergyPlus and more accurate control logic tuning.

Introduction

Kitoshi Tanaka, Chief Researcher at the Research and Development Institute of Takenaka Corporation, and his team are at the forefront of developing advanced air conditioning systems to achieve energy conservation and occupant comfort in ZEB projects. However, even with an energy-efficient prototype design, gaps often emerge between design intent and real-world performance due to mismatches in equipment settings and operational conditions. Recognizing the need to bridge this gap, Takenaka sought to integrate system simulation into their workflow to enable both design optimization and ongoing operational improvement.

Challenge

Because discrepancies between design phase settings and actual operating conditions can often result in higher-than-expected energy consumption, it was essential for Takenaka to fine-tune HVAC control logic—such as air flow rates and temperature settings—based on real operational data. This required a system simulation tool that could model the building environment with high fidelity, capture dynamic HVAC behavior, and integrate seamlessly with EnergyPlus, a building energy simulation platform that models energy consumption and water use, for a coupled analysis approach.

Solution

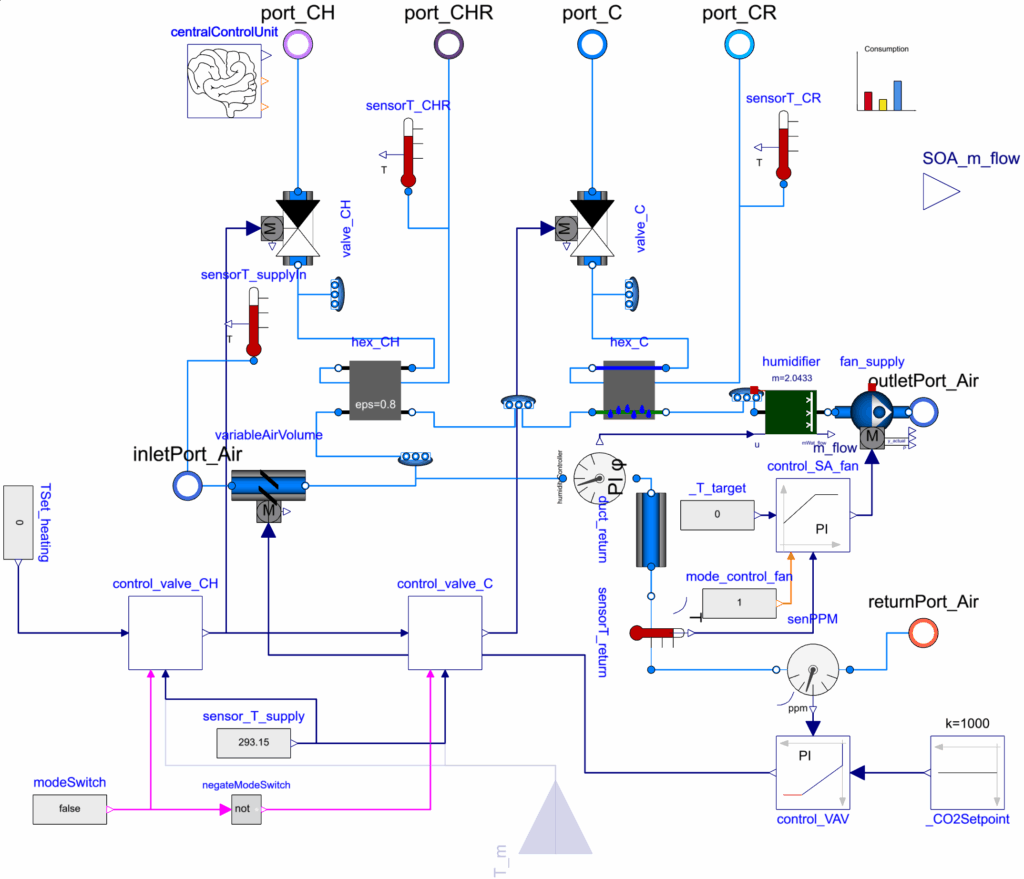

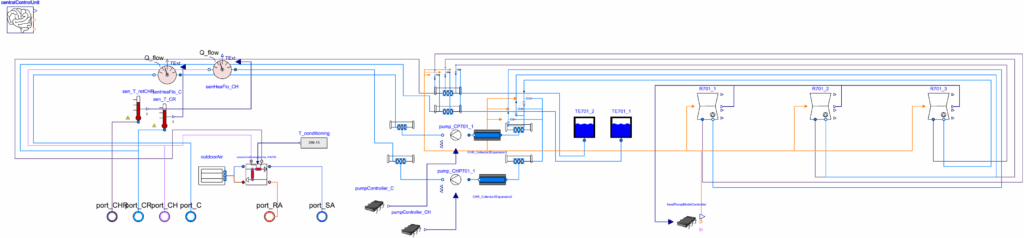

Takenaka selected Modelon Impact for its physics-based modeling based on the Modelica language, robust HVAC-specific libraries, and cloud-based scalability. Modelon’s team guided Takenaka through building a simulation model of a single-floor HVAC system, enabling them to test control logic and optimize settings. Modelon Impact’s intuitive user interface and accessible documentation accelerated the team’s learning curve and facilitated their first experience with coupled simulation using the Modelica Buildings Library.

Key features included:

- Coupled simulation with EnergyPlus for accurate modeling of the building’s thermal zones

- Visual system configuration with an intuitive drag-and-drop interface

- Expert guidance from Modelon experts to streamline model building and troubleshoot issues

“In addition to its extensive library, Modelon Impact features an intuitive user interface that makes it easy to visualize the system configuration, with readily accessible documentation for each component. This made it easy for us to work with the models from the very start” says Kitoshi Tanaka.

Results

Through this collaboration, Takenaka successfully built an HVAC system model including the building energy plant and validated the feasibility of coupled analysis with EnergyPlus. This enabled the team to define optimal equipment settings and control logic, paving the way for improved energy performance during operation. The project also enhanced Takenaka’s in-house simulation capabilities – enabling Takaneka to take on more ambitious simulation projects in the future. The next step of the project includes modeling buildings of medium to large scale and validating these models with operational data.

Takenaka’s partnership with Modelon marked a successful first step towards bridging the design-operation gap in ZEB HVAC systems. By modeling a standard office floor, Takenaka established a foundation for refining HVAC control logic and extending the approach to larger, real-world buildings. With Modelon’s technology and expert support, Takenaka is well-positioned to achieve its vision of energy-efficient and comfortable ZEBs.