Simulating Coolant Distribution Units (CDUs): The Future of Data Center Cooling

Why CDUs are the key to liquid-cooling efficiency and how they can be simulated.

Introduction to CDUs: A Critical Enabler

Data centers are critical to modern society, and their rapid expansion—driven by artificial intelligence, cloud computing, and hyperscale infrastructure—is transforming the way we process and store data. A significant increase in electricity consumption accompanies this growth. In Q1 2025 alone, U.S. data centers consumed an estimated 200 terawatt-hours (TWh), surpassing the 147 TWh used in all of 2023 (Q1 2025 Data Center Activity Report).

Much of this energy powers the ever-evolving microprocessors that fuel these technologies. With the demands of AI, parallel processing, and the Internet of Things, microprocessors are becoming faster and more efficient—but also more power-hungry. The thermal design power (TDP) for microprocessors is expected to reach 700 W this year [1], generating substantial heat that must be effectively managed to maintain optimal performance.

This heat presents a dual challenge. First, cooling accounts for around 40% of the total energy used by data centers [2], placing a significant burden on overall efficiency. Second, air-cooling solutions are reaching their limits, struggling to manage TDPs exceeding 280 W [1]. Finding effective cooling strategies is now critical to sustaining data center growth without compromising performance or energy consumption.

Liquid cooling stands out as the most effective solution to the escalating heat challenges in modern data centers, thanks to water’s heat removal capacity, nearly three times that of air [3]. This superior cooling potential makes liquid systems essential for supporting higher thermal design power and ensuring reliable performance. Solutions range from indirect and direct systems to single- and two-phase immersion cooling, all of which rely on a central coolant distribution unit (CDU) to deliver and manage the liquid’s cooling power.

The CDU is a thermo-mechanical system that integrates key components, including pumps, control valves, sensors, and a heat exchanger, to manage the cooling fluid efficiently circulated between IT racks and the facility’s primary chiller plant. The CDU serves as an interface between the rack-side cooling loop and the chilled water loop, allowing for precise thermal control and isolation of the two systems.

The Simulation Gap: Why Modeling the CDU Matters

To transition from air-cooled solutions to liquid cooling, data center operators require tools that facilitate informed decision-making and planning for the transition. While real physical testing can be employed, this approach is often time-consuming and expensive, particularly when considering numerous conditions and variables. Simulation tools can help accelerate the design and engineering phase of systems by allowing for the virtual testing of hundreds of cases before initiating real-world testing.

However, while there may be multiple simulation tool options for designing and analyzing air-cooled systems, such as computer room air handlers (CRAHs), the same cannot be said for designing CDUs within liquid cooling systems. Current tools lack the flexibility to model CDUs and understand their performance within a model that includes broader data center building infrastructure (e.g., cooling towers, electrical grid, air zones, etc.).

This is where Modelon Impact shines. Built on the Modelica language, Modelon Impact is one of the only tools that offers the flexibility needed to model both air- and liquid-cooled systems effectively. Being a platform that supports multi-domain libraries, engineers can leverage multi-disciplinary system modeling to explore and address key operational challenges, such as creating the optimal balance between air and liquid cooling within a given facility through system sizing, operational cost assessment, and power consumption simulation.

Ensuring a CDU will cool data racks efficiently, even when thermal loads spike or under low-load conditions, and in other extreme cases.

Liquid Cooling at Low and Peak Load: Modelon Impact Simulation Scenario

Focusing on the entire data center in a simulation often leads to overly complex models that are difficult to interpret and act upon. Instead, starting the simulation around the CDU provides a more actionable and insightful approach. CDUs serve as the critical interface between facility cooling infrastructure and IT equipment, making them ideal focal points for evaluating system performance, especially during peak thermal loads.

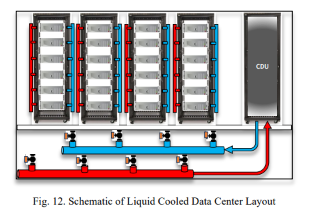

Take, for example, the system model studied by Heydari [4] shown in Figure 1 and its corresponding Modelica model, Figure 2.

The CDU is the subsystem block at the top, characterized by its heat exchanger effectiveness, flow capacity, and supply temperature control. The array of racks that connect can be modified to represent any number of racks with varying sizes and IT heat load profiles. Additionally, the row manifolds can be modeled to capture the pressure characteristics of the system.

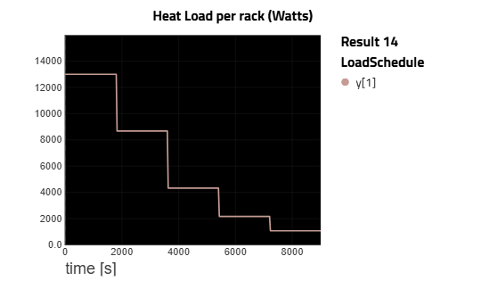

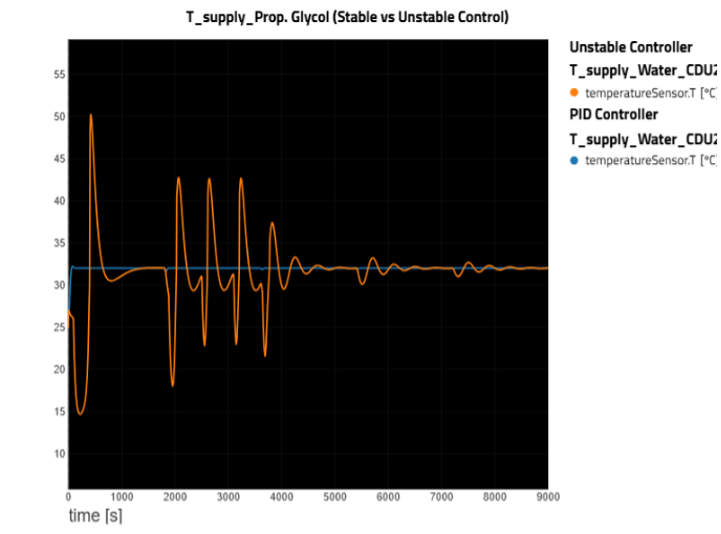

In this example, a central CDU circulates water on the secondary side and 25% propylene glycol on the primary side, which is distributed through the rack manifolds. The CDU was initially tested with a subset of racks under low heat load conditions. As noted by Heydari et al. [4], such conditions can lead to temperature fluctuations on the primary side of the supply. To mitigate these fluctuations, a 3-way valve on the water side adjusts the flow. However, frequent valve actuation—due to aggressive opening and closing—can result in mechanical wear or failure. To address this issue, a controller is required to smooth the valve operation and ensure more stable control. Modelon libraries offer a variety of blocks that can be combined to evaluate control strategies. The simulation was designed to evaluate the control strategies proposed by Heydarii [4], considering the variations in heat load shown in Figure 3. Figure 4 presents the performance of a stable PID controller, contrasted with an unstable configuration. The results clearly demonstrate that a properly tuned PID significantly reduces oscillations and improves system stability.

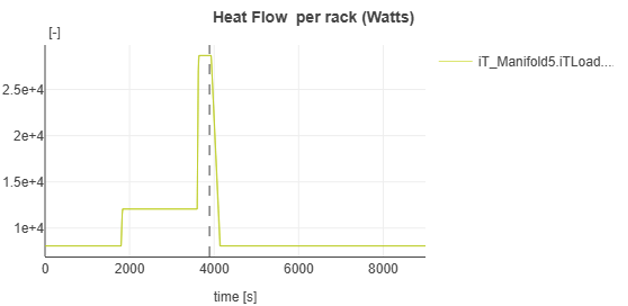

The second test considered the CDU with the full set of server racks and manifolds as shown in Figure 5. An additional PID was included to control the speed of the primary side pump. For this simulation, high load conditions were considered; the heat load schedule is described in Figure 6.

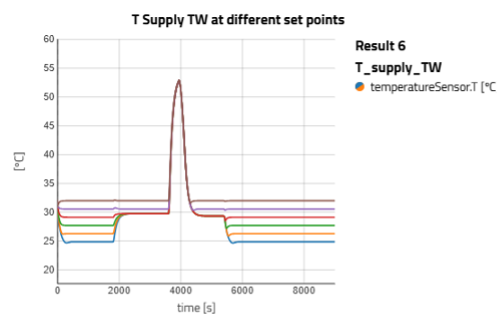

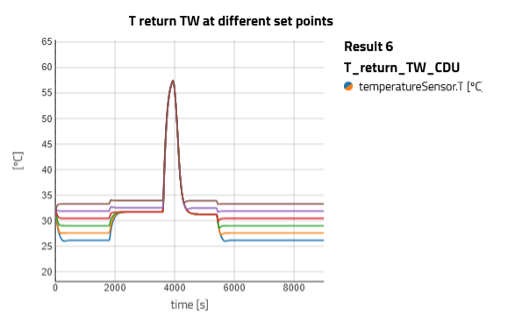

The simulation was configured to evaluate the controller behavior and overall system performance by varying the technical water (TW) supply temperature setpoint from 25 °C to 32 °C. Figure 7 illustrates the resulting supply temperature profile, while Figure 8 shows the return temperature. A distinct peak is observed when a high heat load is applied. The system responds by attempting to stabilize the temperature, exhibiting the dynamic behavior shown.

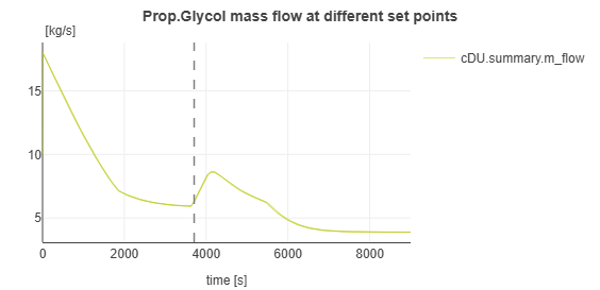

Figure 9 illustrates the variation in propylene glycol flow resulting from the variable-speed pump. The pump adjusts the flow rate in response to the load, initially reducing flow under lower demand and then ramping up to mitigate the peak load.

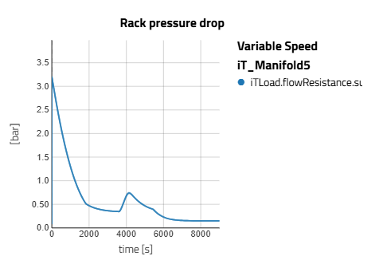

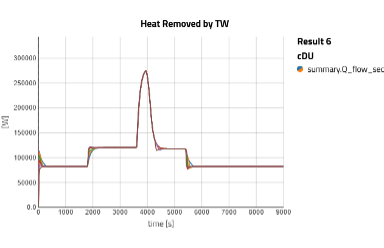

Additional simulation variables are also monitored, including the pressure drop across the racks in Figure 10 and the total heat removed in Figure 11.

The analysis presented is useful for evaluating performance trade-offs and helps data center designers and operators make informed decisions when adopting more efficient, sustainable cooling technologies. This approach can be extended to evaluate CRAH units or hybrid configurations that combine CRAHs and CDUs.

Furthermore, these models hold strong potential for integration into Digital Twin frameworks. By continuously synchronizing with real-time operational data, these models can support predictive maintenance, anomaly detection, and dynamic optimization of cooling strategies. Digital Twins can also serve as decision-support tools for capacity planning, energy efficiency benchmarking, and assessing the impact of configuration changes without disrupting system operation.

CDU Simulation for Industrial Collaboration

Modeling CDUs is not just for research groups or CDU manufacturers; it is also beneficial for other stakeholders. It can also be leveraged by consumers of CDUs to understand what CDU performance is needed before exploring product offerings.

Using the FMI standard and Modelon Impact’s native sharing features such as App Mode, CDU models can be shared and utilized in various tools that support the standard, making it easier to share models while protecting IP by only exposing required inputs and outputs. This enables the receipt of CDU models from manufacturers and their seamless integration into data center models to verify compatibility. Alternatively, data center operators can share their plant model with CDU manufacturers to either recommend an existing option or design a custom unit.

CDUs are the backbone for the next generation of data center cooling solutions. It is a necessary step to accommodate the exceeding TDP of microprocessors in data centers to meet the expected processing demands. By using Modelon Impact to model and simulate these CDUs with their adjacent systems, data center design engineers can enhance system design and control strategies for cooling systems, resulting in faster and more cost-effective online deployment compared to conventional testing methods.

To learn more about how Modelon Impact and Modelon technical services solve your specific cooling challenges, contact our team today.

References

[1] “AMD: Addressing the challenge of energy-efficient computing,” VentureBeat. Accessed: May 05, 2023. Online. Available: https://venturebeat.com/data -infrastructure/amd-addressing-the-challenge-of-energy-efficient-computing/.

[2] Y. Zhang, K. Shan, X. Li, H. Li, S. Wang, Research and technologies for next generation high-temperature data centers – State-of-the-arts and future perspectives, Renew. Sustain. Energy Rev. 171 (Jan. 2023) 112991, https://doi. org/10.1016/j.rser.2022.112991.

[3] A. Habibi Khalaj and S. K. Halgamuge, “A Review on efficient thermal management of air- and liquid-cooled data centers: From chip to the cooling system,” Appl. Energy, vol. 205, pp. 1165–1188, Nov. 2017, 10.1016/j. apenergy.2017.08.037.[4] Heydari, A, Shahi, P, Radmard, V, Eslami, B, Chowdhury, U, Hinge, C, Reddy Cinthaparthy, LS, Miyamura, H, Modi, H, Agonafer, D, & Rodriguez, J. “A Control Strategy for Minimizing Temperature Fluctuations in High Power Liquid to Liquid CDUs Operated at Very Low Heat Loads.” Proceedings of the ASME 2022 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems. ASME 2022, https://doi.org/10.1115/IPACK2022-97434