Real-time Simulation of an Aircraft Aileron Actuator

This blog is Part 4 of a blog series that demonstrates how the Modelon Hydraulics Library can be used for the model-based development of an Aircraft Hydraulic Actuation System (AHAS). In this series, basic steps of the actuation system development workflow will be covered.

Previously, Part 2 and Part 3 focused on the modeling and simulation of electro-hydraulic actuator with datasheet-based parametrization. Part 4 – below – is dedicated to simulating the simplified aileron model in a real-time target.

The Importance of Real-Time Simulation

During the development of a Fly-by-Wire actuator and its control electronics, the trimming of the actuator control laws is of particular importance. While most can be performed with simulation on a standard computer, one relevant step is to include the control laws on a real-time target that controls the physical model (plant model) inputs. These two models are usually not coming from the same software.

This plant model shall react in real-time – i.e. the computation of every simulated time step takes less time than the simulated time itself – to avoid that the model would be delayed compared with real-time orders (this would be a task overrun). This real-time integration enables validating the actuator control laws with more accuracy.

In this blog post, we will illustrate how the simple actuator model developed in the blog post 2 is integrated in a Speedgoat target and runs real-time.

Minor Model Adaptations

The changes made on the model are the following:

- Isolation of the plant model (the simple control logic would be in the real-time target implemented in Simulink®).

- Addition of a few outputs monitoring the pressures, flow rate and force of the plant model – to have an easier access to and plotting of these.

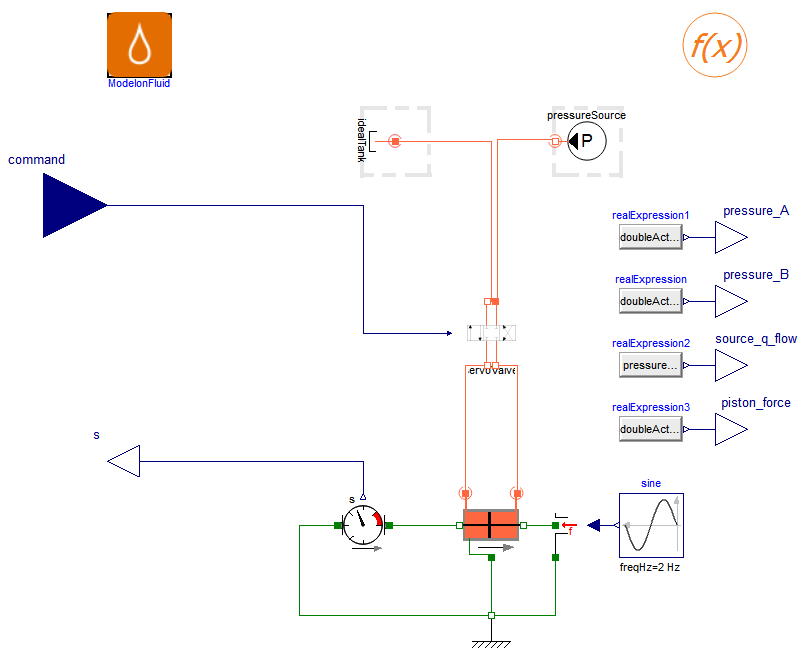

Figure 1 below displays the final version of the model.

Integration on the Real-Time Target

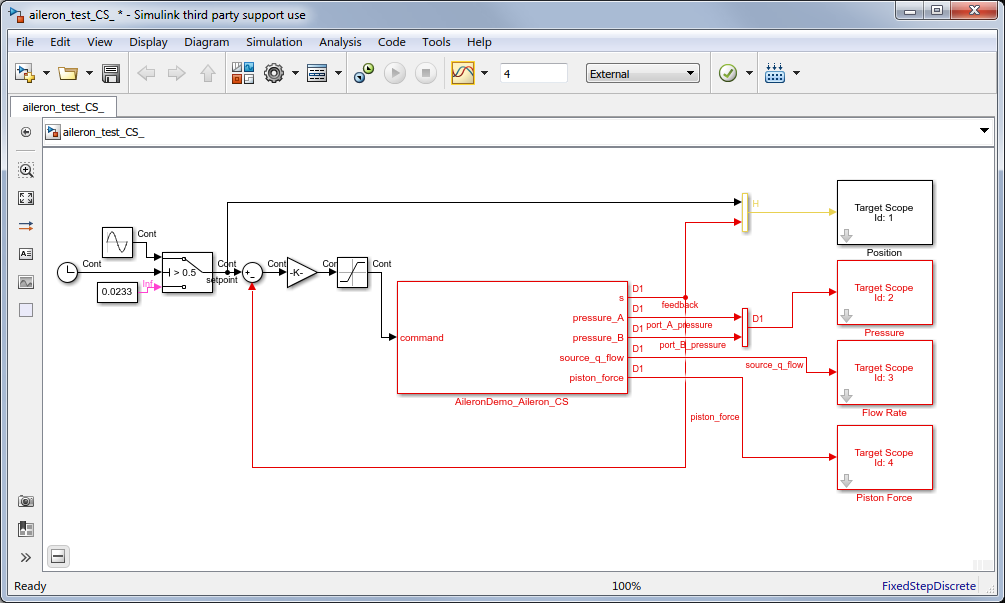

The integration in the Real-Time target consists of a few steps:

- Coding in Simulink® the control/command blocks of the actuators.

- Including the Modelica model made from Modelon Hydraulics, exported as an FMU, using FMI Toolbox developed by Modelon.

- Adding Speedgoat specific blocks to monitor the variables of interest.

- Build the real time executable using the Simulink Real-Time™ target.

In this application, the plant model has been exported with its own solver (co-simulation) so that both the control and the plant model have separate solvers and the models communicate at each time step.

Real-Time Simulation of the Integrated Systems

Once the model is integrated and imported on the real-time target, it is run satisfying hard real-time requirements. The main variables set as output previously are plotted here:

- Top left: actuator command and response. We observe an initial position of the actuator on-purpose different from the command leading to a fast transient at the beginning of the simulation. After reaching the setpoint, the actuator reacts in a satisfactory dynamic behavior, slightly influenced by the antagonist loads.

- Bottom left: the flow exiting the ideal pressure source is plotted. The dynamic observed is a redressed sine similar to the actuator position response. The frequency is doubled as the flow is provided in both positive and negative speeds of the actuator.

- Top right: the pressure in both chambers are observed. These are oscillating around an average point, in phase with the force oscillation shown at the bottom right.

Conclusion

In this short blog post, we have illustrated the capabilities of exporting a Modelon Hydraulics Library model and integrated into Simulink® for running the control and plant models in co-simulation on a real-time target.

This demonstrator also illustrates that the same model can be used for different use cases – here, standard simulation and real-time simulation on a HiL target.

Stay tuned to find out the remaining interesting parts of the series covering full system performance analysis and component detailed design.