Creating a Virtual Test Bed for Next-Gen Industrial Heat Pumps

For over two centuries, MAN Energy Solutions (MAN ES) has been at the forefront of technological advancements that drive societal progress. Recently, the company has shifted its focus towards pioneering decarbonization as an energy systems design and industrial solutions provider.

As part of this sustainable approach, MAN ES has been researching and developing large-scale industrial heat pumps, which are vital for creating sustainable heating solutions for industries and municipalities. MAN ES developed the first large-scale transcritical CO2 heat pump (so-called “Mega Heat Pump”) that absorbs heat from low-temperature sources (e.g., sea water or air), transfers it to a working fluid through compression and then releases it to higher-temperature sinks for heating or cooling. CO2 is non-toxic and non-flammable, and using it as a refrigerant instead of conventional hydro-fluorocarbon refrigerants is environmentally friendly due to its low global warming potential.

MAN’s heat pumps are versatile and can be customized to meet specific customer needs. With a temperature supply range of approx. 60 to 150°C, they are suitable for heating water and liquids, e.g. process heating, district heating. Their power output ranges from 10 megawatts thermal (MWth) up to 50 MWth per unit, with the potential for even higher outputs through the parallel operation of multiple heat pumps.

Challenges

Transcritical CO2 heat pumps operate at higher temperatures and pressures than traditional heat pumps, offering greater efficiency with lower emissions. Designing these systems requires specialized components and precise engineering, as even a slight increase in efficiency can significantly reduce CO2 emissions. Tailoring solutions to specific climates and system scales further complicates the development process. Building long-lasting systems is also challenging due to niche operating events over extended periods. Anticipating system responses to varying conditions over time is crucial, as post-deployment changes are costly and time-consuming. Accurate transient simulations are essential to improve short- and long-term design decisions. Such models enable MAN ES to study the system behavior in a virtual test bed over extended periods and under varying conditions, looking into the operation throughout a day, throughout a year, and optimizing the control strategies.

In this regard, MAN ES employs dynamic models for transient simulation as an integral part of their development process to:

• Simulate real-world conditions: Dynamic transient models optimize performance and efficiency under varying conditions.

• Enhance control and stability: Understanding transient responses ensures system stability and prevents issues.

• Optimize energy use: Accurate transient state modeling reduces waste and improves efficiency.

• Integrate renewables: Adapting to fluctuating energy supply enhances district heating network flexibility and sustainability.

• Embrace Industry 5.0 and Digital Twin: A Digital Twin provides real-time model updates, personalized product representation, and improved decision-making throughout the product lifecycle.

Solutions

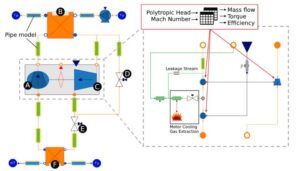

In the past, MAN ES performed simulations in steady state, but for cyclic thermodynamic processes, it’s important to see how a shutdown, a start-up, a ramp-up, or any transient part load operation can perform. MAN ES chose Modelon Impact to develop a detailed transient transcritical heat pump model and simulate their heat pump under diverse scenarios. These scenarios include system response under various loading profiles like shutdown, start-up, electrical load balancing and any other, sudden change in the system inputs.

One advantage of Modelon Impact is accessing built-in, Modelica-based component libraries while retaining the option to use third-party and open-source libraries in a drag-and-drop user interface. Modelon’s Thermal Power and Vapor Cycle libraries gave the MAN ES team a strong starting point to customize components further and model the system precisely.

Emmanuel Jacquemoud is the Principal Engineer of Electro-Thermal Energy Storage/Heat Pumps for MAN ES. When asked about his team’s experience getting started with Modelon Impact, he said, “We regularly have PhD students and new team members working on modeling. They can learn Modelon Impact in a couple of months and further develop our capabilities. I don’t think that is possible with all the simulation tools. The Modelica framework and the Modelon Impact platform are very accessible.”

Once the model was complete, MAN ES began running simulations to analyze the heat pump’s behavior and limitations. Understanding the heat pump’s response to varying load demands helps MAN ES prepare for commissioning. As a first step, a physical test bed was built at MAN ES’s facility in Zurich, Switzerland. A model of the test bed was developed in Modelon Impact, and simulations were conducted to replicate tests performed on a physical test bed.

Results

To validate the model, physical tests of the 35 MW transcritical CO2 heat pump were performed at the Zurich facility, giving MAN ES a data set to compare with the heat pump model’s simulation results.

The heat pump model matched the physical test bed measurements with an accuracy of 95% for the relevant process parameters. These simulations helped MAN ES to adjust their control strategies and even re-think some design aspects for their future projects.

With a full-scale heat pump deployment in Esbjerg, Denmark, the team will compare simulation results with real-world conditions and fine-tune the model for future projects. Using energy from seawater and renewable electricity to generate heat, the Danish city is on track to eliminate 160,000 tons of CO2 emissions annually at one site with MAN heat pump technology.

Emmanuel Jacquemoud believes modeling and simulation can add even more value for MAN ES’s customers, saying, “Ultimately, we would like to offer a simple simulation tool to our customers. A dynamic digital twin would allow them to run simulations, create forecasts, and determine operating plans.”

Having a validated model with trustworthy results encouraged MAN ES to continue developing a dynamic model with Modelon Impact for future projects in Denmark, Finland, Sweden and other European countries.