電力網のための水力発電の安定化

Hydro-power is often associated with conservative and perhaps stagnant technology development. But, because it has been around for hundreds of years and many countries rely on the output of power, the maintenance and continued support of these plants is critical. Currently, in Iceland 70% of their electricity is produced from hydroelectric power, therefore constant operation of hydro-power plants is critical for deriving electricity.

This blog piece summarizes how researchers at Verkis hf and the University College of Southeast Norway utilized Modelon’s Hydro Power Library and Electric Power Library to develop models needed for studying the dynamic characteristics of Iceland’s Fossarvirkjun hydro power plant – serving the Súðavík municipality. By developing a model consisting of the hydro power plant and the electric grid it serves, researchers could better understand plant characteristics such as load rejection and exploring worst-case scenarios in case of a full-shut down of the plant would occur.

Model Development

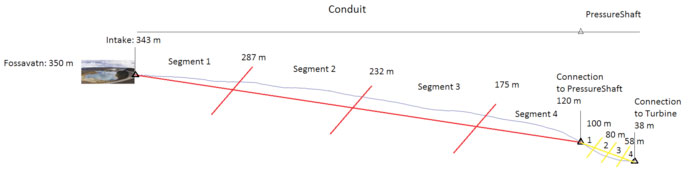

The water-way model (Figure 1) of the 1200 kW Pelton turbine consists of a head source, reservoir (Foosavatn), conduit, closed volume and pressure shaft. Mass, energy and momentum balances describe the pressure and water inertia phenomena and can predict the water hammer effect and pressure rise in the pressure shaft.

Figure 1 Water-way of Fossarvirkjun.

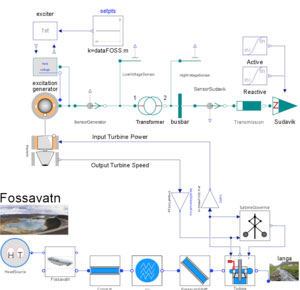

The electrical grid consists of a synchronous generator, step-up transformer from 0.4 kV to 11kV, a 5km transmission that carries the alternating current to the customer. It includes an exciter system controlling the voltage and reactive power while the active power is controlled by the governor.

Figure 2 Hydropower including the electrical grid and control system.

To verify the accuracy, a dynamic load rejection scenario was simulated and compared with data from the manufacturer.

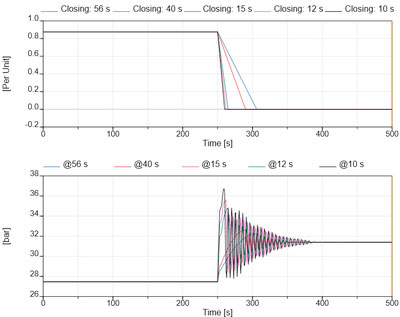

Next step was a closing time analysis on the water-way. A fast closing time would ensure that the plant can react rapidly to changes in the grid and be quickly shut-down in case of an emergency. A limiting factor is if the pressure rise which needs to be below the rated maximum pressure of 32 bar 15% to avoid equipment and safety failure.

Results:

The result from closing time simulations as shown in Figure 3 was used to estimate a limit on the closing time yielding a quicker hydro power operation that more quickly can react to critical disturbances.

With a stabilized hydro-electrical plant the greater electrical grid is prepared to better handle disturbances and safety critical scenarios, while also improving the reliability and grid quality, and avoiding potential damages and tear on expensive equipment.

Figure 3 Pressure in pressure shaft at various closing times.

Credits:

The research demonstrates the necessity of model-based development where safety and emergency shut-down can be simulated in a safe-virtual environment. It also shows how Modelon’s Hydro Power and Electric Power library can be combined to develop a detailed model of a hydro-electrical system. Download a copy of the paper here.