石炭火力発電所におけるCO2吸収統合プロセス

It’s no secret that global governments are implementing greenhouse gas policies aimed at reducing CO2 emissions. These policies have a direct impact on the power generation sector as carbon capture and storage technologies are essentially the only option available for fossil-based power generation to drastically reduce their CO2 emissions.

So, how will they do it?

Investigation of new operating requirements and implementation of innovative technologies is best done using model based system simulation techniques. Knowing this, Chalmers University of Technology in Sweden, has utilized Modelon libraries to develop a dynamic model of a CO2 absorption process, integrated in a coal-fired power plant.

Model Development

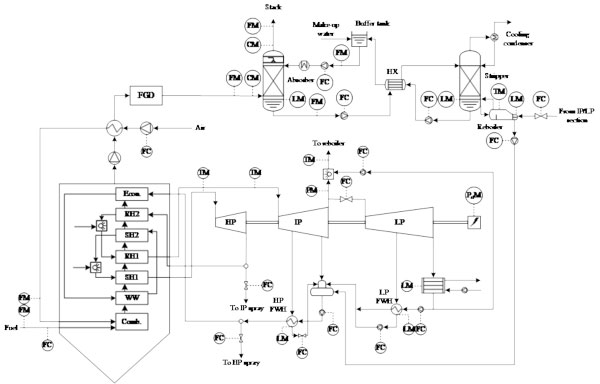

The dynamic model consists of two main parts, the power plant and the absorption plant. A schematic of the modeled system is shown in Figure 1. The power plant is a supercritical, single-reheat, pulverised fuel (PF) fired plant and is a typical representation of a modern power plant and its dynamic characteristics.

The power plant model incorporates the main aspects of state-of-the-art PF power plants operated in Europe, such as sliding-pressure operation, steam reheating, multiple-stage turbines, and a feed-water heating (FWH) system and an outlet temperature control for live and reheat steam.The power plant model mainly comprises components from Modelon´s Thermal Power Library. Design data from a reference power plant (Nordjyllandsvaerket in Denmark) is used to dimension several of the modeled components.

The CO2-absorption process considered is a standard MEA cycle.The dynamic CO2-absorption process model is based on a detailed reaction model that has been constructed in the steady-state simulation software Aspen Plus and subsequently implemented in the dynamic modeling environment of Dymola. The dynamic model of the CO2-absorption process consists of components from Modelon´s Gas-Liquid Contactors Library.

Figure 1: Process schematic of the connections between the steam cycle and the CO2-absorption process with a throttled LP turbine configuration used for steam extraction. Controllers (C) and measurement points (M) for pressure (P), flow (F), temperature (T), gas composition (C), and liquid level (L) are indicated in the figure.

Results

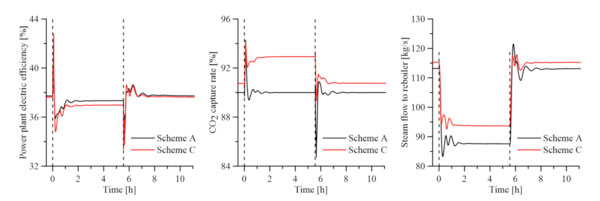

The dynamic operation of the integrated system was studied under two modes of operation: (i) varying the power plant load and (ii) varying the availability of steam for the CO2-absorption process. A part of the work included evaluation of several control schemes with different operational objectives in the integrated system. The effects on various process parameters such as power generation and steam draw-off to the CO2 capture plant were studied. Examples of results from the model simulations are shown in Figure 2, for operation in variable power plant load. Two control schemes with different operational objectives are implemented (Scheme A – CO2 capture rate is an operational objective, Scheme C – CO2 capture rate is disregarded).

Figure 2: Example of results from Dymola – responses in a power plant with CO2 absorption for a load profile of 90-70-90%.

Key results from the study can be summarized as follows:

- During load transitions in a power plant with CO2 absorption, the power generation stabilizes much faster, generally in under 10 minutes, than the CO2 absorption process, which typically requires more than an hour to reach steady-state operation.

- When varying the power plant load, the CO2-absorption process does not significantly affect the load-following capabilities of the power plant in terms of power output. The choice of control scheme for the CO2-absorption process is of importance, as pairing of control variables in relatively slow control loops results in the power output stabilizing in up to 30 minutes.

- When varying the availability of steam for the CO2-absorption process, power output can be increased at the expense of increased CO2 emissions, although significant fluctuations in process variables are observed. However, a power plant owner can increase the maximum power output and still be able to participate in a day-ahead energy market, where electricity is sold by the hour.

- Modeling and simulation is a key enabler for significant improvements in plant design and operation.

References

Garðarsdóttir, S. Ó.; Montañés, R. M.; Normann, F.; Nord, L. O.; Johnsson, F., Effects of CO2-absorption control strategies on the dynamic performance of a supercritical pulverized-coal-fired power plant. Industrial & Engineering Chemistry Research, 2017, 56, pp. 4415-4430. http://pubs.acs.org/doi/10.1021/acs.iecr.6b04928