炭素回収貯留 (CCS) 技術でフレキシブルな発電所操業を次のステップへ

This blog is a detailed follow-up to Modelon’s webinar “Integrating Carbon Capture and Storage Technology Using Simulation”. Watch the free webinar here.

Decarbonization of the power sector is steadily growing to be a global necessity for sustainable development. In power systems with increased shares of renewable energy sources (including wind and solar) flexible operation of thermal power plants is crucial for balancing the variability increase of net load while maintaining the security of supply. For these reasons, highly efficient and flexible thermal power plants with low specific emissions are needed to ensure the successful transition towards decarbonized power systems.

But how do we achieve a more flexible and low emission thermal power plant? One method is Carbon Capture and Storage (CCS) technology. Proven at a commercial scale for retrofitting coal power plants in North America, CCS technology allows for up to a 90% reduction in the carbon emissions of thermal power plants. However, while modern combined cycle power plants are quite flexible, a chemical process such as post-combustion CO2 capture with amines is characterized by relatively long stabilization and dead times, sometimes taking a few hours to stabilize after a small disturbance. In contrast, the thermal power plant load change events require only a few minutes to reach stabilization. To understand the aspects of process integration, control and dynamic interactions between the thermal power plant and the chemical absorption process during flexible operation events, simulation technology steps in as a key enabler.

In this blog, researchers at The Norwegian University of Science and Technology (NTNU) study the effectiveness of CCS technology by utilizing Modelon libraries to develop a dynamic model of natural gas combined cycle (NGCC) power plant with post-combustion CO2 absorption process.

Dynamic process models of post-combustion CO2 capture

When trying to understand the dynamics of complex processes, factoring in the scale of the system is a necessary step. Conducting tests and obtaining knowledge of system behavior and control at a demonstration scale is extremely valuable for successful scaling of the process from system models.

The Separation Process Library, a non-commercial add-on to Modelon’s Thermal Power Library, was utilized to develop a dynamic process model of the chemical absorption process for CO2 capture of a large-scale pilot plant. The pilot plant model was developed in a collaboration between NTNU and Technology Centre Mongstad (TCM), a test facility in Norway known as the largest facility for testing and improving CO2 capture technologies.

Validation and Deployment of Test Model

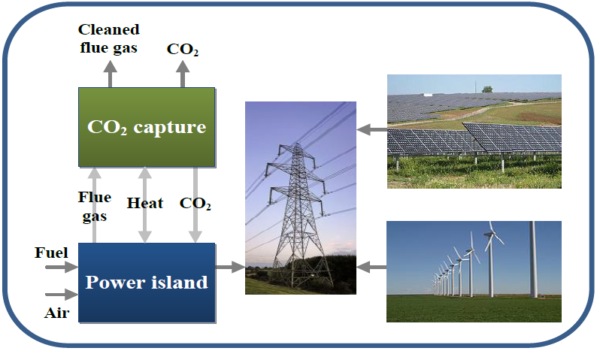

To obtain trustworthy simulation results, the model first needed to be validated. Data sets were obtained from test campaigns conducted at the amine plant at TCM operated with the benchmark monoethanolamine (MEA) solvent. The amine treats a slipstream of flue gas originated at the combined cycle combined heat and power plant placed next to Mongstad refinery in Norway (see Figure 2). The generated data sets represent a wide range of steady-state operating conditions and transient events were employed for dynamic process model calibration and validation. As a research facility, more than 1000 instruments are available at the amine plant at TCM for monitoring the process. During the validation process, large amounts of process data need to be processed. Here, FMI tools from Modelon proved to be very helpful for performing post-processing of simulation results and compare with reference plant data.

The thoroughly validated model was then employed to analyze the process dynamics at different power plant operational loads and to evaluate the performance of decentralized control structures applied during the absorption process The key results from the simulation work can be summarized as:

- The validation demonstrated dynamic process modeling capabilities applied to large scale experimental data.

- The simulations provided understanding and mapping the process dynamics at different plant loads.

- The evaluation of decentralized control structures for optimal operation of the process in response to fast load changes from the power plant.

The knowledge gathered and lessons learned from extensive process simulations were utilized to develop transient tests that were applied at the amine plant during a later test campaign. In preparing the test matrix, the process models also proved very useful. Key benefits of using dynamic simulations during test matrix planning can be summarized as follows:

- Deep understanding of process dynamics can help to conduct parametric testing at a pilot plant with faster stabilization of the process, leading to saving in time and operational costs (or allow for more tests in a given time framework).

- Pre-tuning of controllers of the supervisory control layer can be conducted via dynamic simulations, which leads to more efficient tests and reduces the need for onsite tuning.

- Preliminary results from dynamic simulations help to communicate with operators and process engineers at the plant during the test planning phase, making easier to communicate the purpose of specific tests across multidisciplinary teams.

- Model-based system simulation with Modelica technology proved to be a key enabler for control structure design and implementation.

The experimental results from the test campaign provided empirical evidence at demonstration scale that thermal power plants with post-combustion CO2 capture can be operated with similar operational patterns as unabated power plants, even for fast load changes in the power plant. The capture process can be stabilized and brought to desired operating conditions by employing decentralized control structures within less than 1 hour

Scale up and integration with NGCC power plant

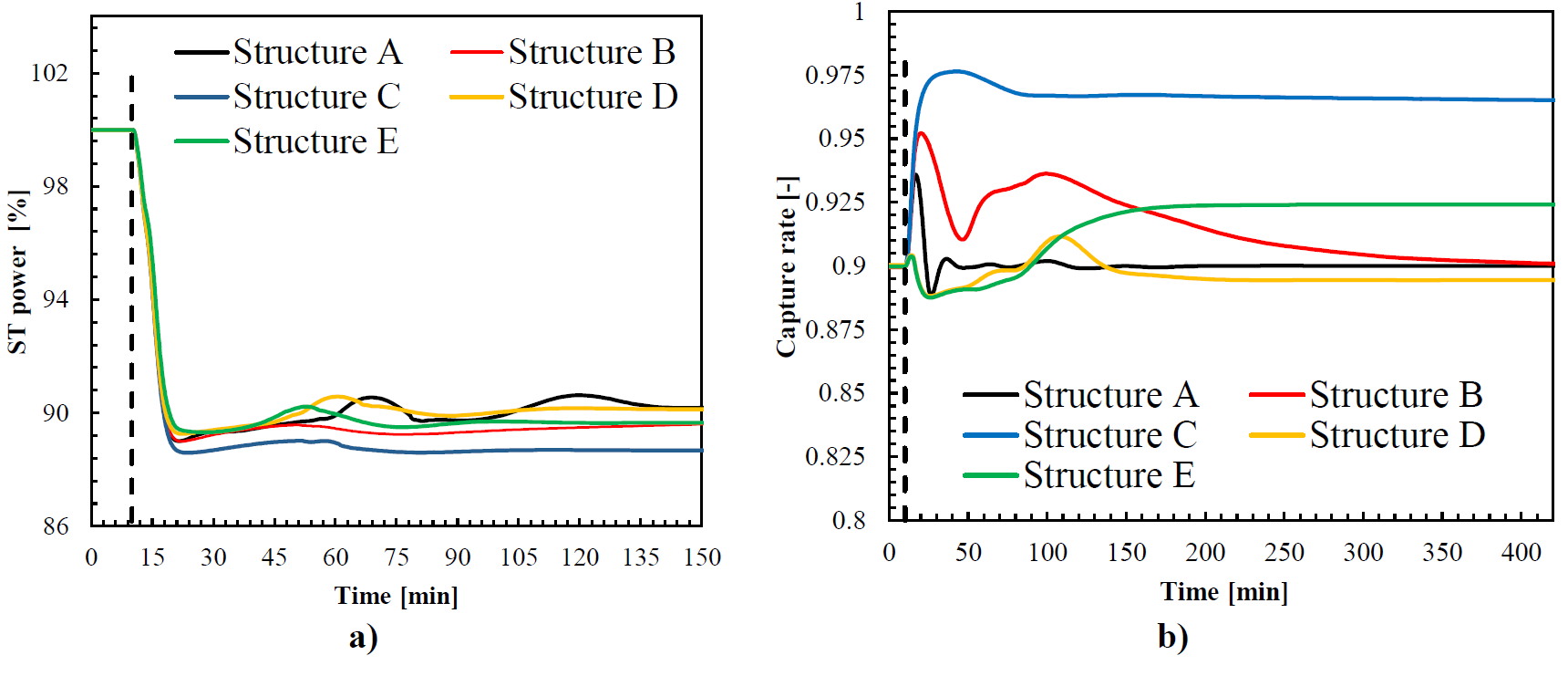

In order to assess the integrated performance of the chemical absorption process and the thermal power plant during transient events, the post-combustion CO2 capture process was scaled up and design was proposed considering its integration with a combined cycle power plant. A dynamic process model of the NGCC plant was developed by means of Thermal Power Library (TPL) in Modelica. The process models of the power plant and the capture process were linked and co-simulated, allowing for simulations of a virtual power plant with CCS Dynamic simulations allowed to analyze dynamic interactions between the integrated systems during load change transient operation (see Figure 3).

- Detailed and linked dynamic process models of a complex process such a power plant and post-combustion unit can be simulated in Modelica-compliant environment.

- Operation of a commercial power plant with CCS is demonstrated via dynamic process simulation.

- Control of L/G ratio of the absorber columns leads to close to optimal part load steady-state performance and significantly fastest stabilization times of the power plant and PCC unit’s main process variables under fast load change events.

- It is concluded that adding the PCC unit to the NGCC does not significantly affect the practical load-following capability of the integrated system.