ライトニング・マックィーン、ディズニー・ピクサー・カーズと私の一日

Explaining the ins and outs of working at Modelon is never as transparent as it should seem. After watching Cars 3 with my son I found an easier way to explain the challenges customers have and the benefit of model based engineering. Read on….

What do you do for a living? An intrusive question but, nonetheless, a valid one for family and friends to ask and receive an answer to. So, let me attempt to simplify the topic for those of you who may have interest.

Cars, the movie created by Disney Pixar, and the leading character, Lightning McQueen, is a family favorite in our house. So, in Cars 3, when Lightning McQueen is pushed out of the sport he loves by Jackson Storm, I (from an engineering perspective) am happy to see that proper model-based engineering techniques come into play.

To summarize the situation, the following clip shows what happens if you deploy model-based techniques properly.

Let’s walk through how the new generation of racer is utilizing the power of model-based methods properly and how Modelon can help you navigate each of the following phases.

Phase #1 – Develop Your Vehicle Model

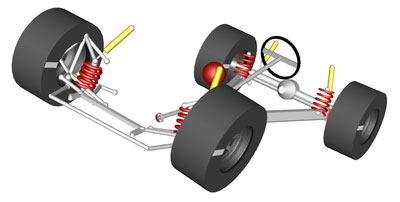

First thing you need is a model of your car (or the car you want to build), may it be Jackson Storm, Lightning McQueen or any other type like Formula One, NASCAR, Formula E. We have a library with all necessary component models, architectures and example vehicles to quickly get you going in creating your own vehicle model. The picture below shows the car model ready to apply in our model-based engineering quest.

Phase #2 – Design The Optimal Race Line

Finding and maintaining the right race line is critical to speed. In order to design the optimal race line a large amount of snapshots are taken from all around the race track. For each snapshot we can explore how unique driver input and car settings affect the performance. Then, we chain the points together to get the complete lap. Easy? Yes, but since you want to evaluate each snapshot multiple times to find the right speed and posture of the car, as well as the right driver input, you end up with a lot of calculations. Therefore, the car model must be very fast to execute. To do this, a steady-state solver is applied to the model, which allows us to get the data we need back within a fraction of a second.

Phase #3 – Simulator Training

Next thing is training. A critical factor for Jackson Storm’s success it that he has been experiencing the races repeatedly in the simulator – the same success can be seen with any driver. The simulator lets you know the limits of the car, and enables the engineers figure out what settings fit for a given driver’s style. Again, we start with our model we already have, and this time we export it to the simulator. We do this by applying another solver that ensures that we can calculate how the vehicle behaves given the driver’s input and then swiftly feeds back the information how the car moves so that visual, audio and motion feedback can be given to the driver in time for the right experience.

Phase #4 – Assess, Analyze, Adjust

In the video, the importance of downforce is highlighted. In racing applications where speed is critical, any aerodynamic effect is very sensitive to how the car sits on the track, meaning how low and at what attitude the body has, as it influences the air stream under the body. So, the coupling effect is important to gain the last percentages that define the winner. Since we have a vehicle model, optimal race line, simulated driver information, we can use the calculations to accurately represent how the car motion interacts with the aerodynamics in a CFD simulation, or to produce input to a wind tunnel test.

Go McQueen!

These are just examples of all the different things you can do with the one model you have made. Taking up the fight with the next gen racers? Now you know how you do it.