What is Physical System Simulation?

Physical system simulation can make a substantial impact in reducing design and operation costs while accelerating the time to market for new products. Physical system simulation is an elusive concept – yet on your journey to virtualize the product design process, there is no way around it. In the first blog of the Success with Simulation Series, Pieter Dermont, Modelon’s Senior Business Development Director, covers what physical system simulation is, what it is not (hint, it is not “systems engineering”), and what it can do for your organization.

Physical System Simulation Offers the Right Fidelity to Make Decisions on the System Level

In the world of simulation, one always deals with a trade-off between the detail in the model and the computational time. A model is a description of the physical world in more or less detail, and the more detail that needs to be simulated, the more computationally expensive the task will be. Computationally expensive models will take longer to simulate, and while that may be necessary in some cases, it’s often a better approach to include the right amount of detail to achieve faster simulation results. Faster simulation results mean that an engineer can update the design (and subsequently the model)more often, then experiment and iterate faster throughout the product design cycle.

For instance, some simulation methods allow you to capture a high level of detail while being relatively computationally expensive. They are often used for component-level simulation in 2D or 3D and are often limited to interactions of one or two physical domains. Computational Fluid Dynamics and Finite Element Analysis are methods that typically fall within this category. Computational Fluid Dynamics is focused on fluid flow only, possibly with interactions of the chemical or thermal physical domain. Though, for simulating systems these methods are computing cost prohibitive. Instead, for system simulation, the focus is predominantly on the 0D or 1D effects.

For the simulation of a system, and to achieve meaningful and timely engineering insights on a system level, the question then becomes: what details or physical phenomena should be included in the model?

Physical system simulation is focused on representing a system, and thus sacrifices component detail in exchange for faster performance and the ability to capture the complete system. This does not mean that system simulation is less accurate or less predictive -all paradigms require their due diligence in terms of parametrization, calibration, and validation. Rather it means that system simulation is focused on capturing the physical phenomena that are relevant on a system level.

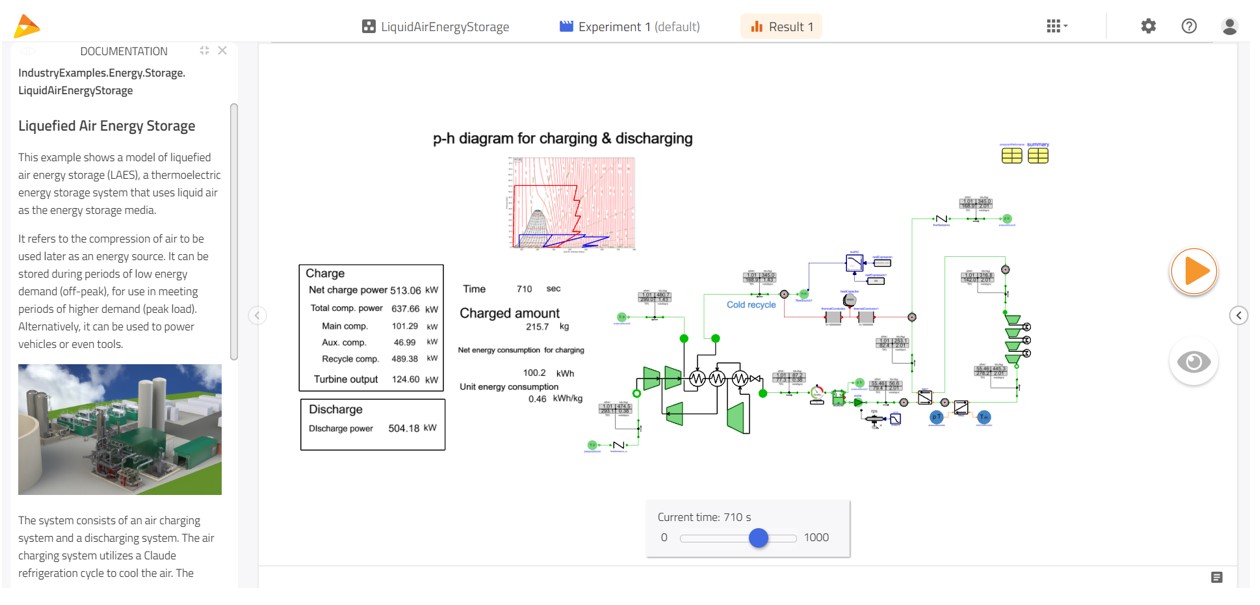

For example, in Figure 1, the liquefied air energy storage system model includes the right level of detail relevant to the whole system analysis. This model can track the thermodynamic state of the fluids as they are changed by each cycle component, according to the transformation the fluid undergoes in each component. As such, decisions on the system level can be made.

Predictive Capabilities Using Physical System Simulation

Physical system simulation offers features to accurately describe physics. When an engineer is required to find the right description of her/his physical system, it is crucial to use a simulation paradigm that represents the ‘physics’ conveniently. This physical description is possible thanks to two key capabilities of physical system modeling:

- First-principle equations are the fundamental laws that govern our physical world, such as the conservation of mass, energy, and momentum. These laws also govern the behavior of physical system models.

- Empirical relationships describe phenomena such as pressure losses, heat transfer, and friction that cannot be conveniently modeled using first principles at the system level. These empirical relationships are determined by experimental research and often parameter-fitting practices.

The combination of these two gives physical system simulation its predictive capabilities, and a leg up compared to purely data-based approaches for simulating physical systems. This foundation permits building models that accurately represent a variety of physical domains, such as mechanical, fluid, heat transfer, electrical, chemical, and/or magnetic physical phenomena. Andthuscapturesthe interactions of the domains – the creation of multiphysics system models.

A good physical system simulation tool will bring features that are relevant to simulating physical systems, as opposed to any system. Such features include the ability to work with units for physical quantities, group quantities, and models, reuse first principles, and select the relevant empirical relationships conveniently. Complexity grows rapidly and exponentially, and those features become paramount to the handling of the model. To contrast this, using well-established general-purpose or scientific scripting languages to represent a physical system rapidly adds unnecessary complexity to the description of the model. Complexity is detrimental to the speed and quality of the product development cycle. A design engineer can be prone to human error, whereas the correct physical system simulation tool can help combat this and speed up product design iterations.

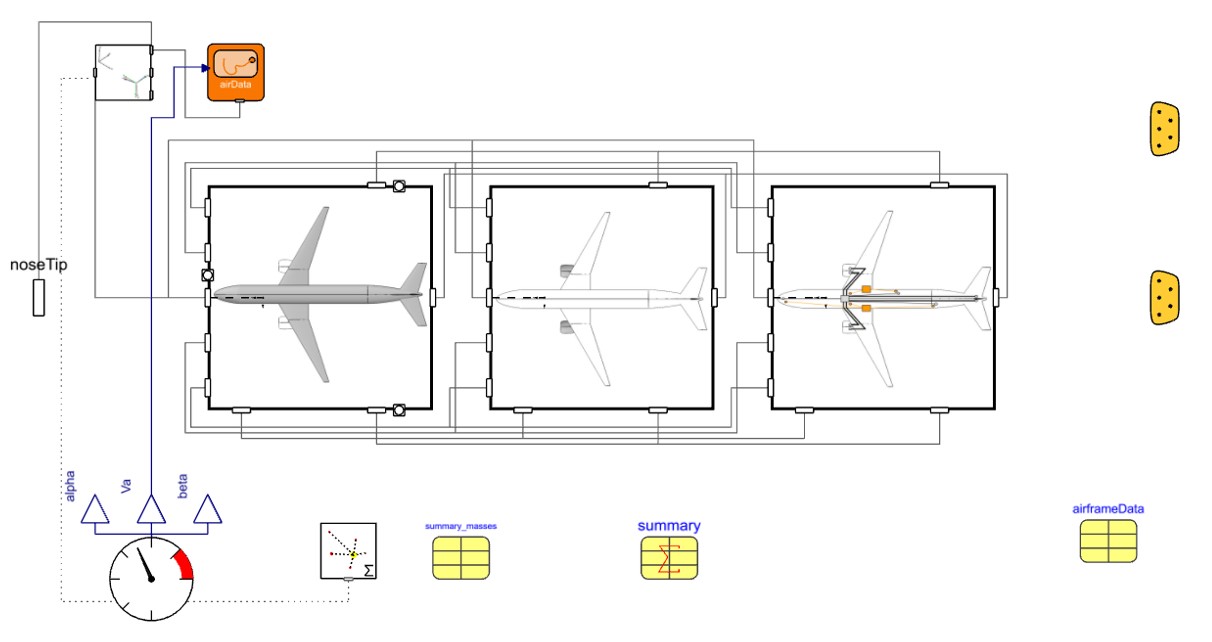

The model in Figure 2 shows a physical system simulation that’s focused on the predictive physical phenomena of an aircraft on the system level, covering the various physical domains relevant to each aircraft subsystem. The behavior of each subsystem is governed by first-principle equations and empirical relationships. Modelon library content offers a collection of numerically robust, performant, and re-usable first principle equations and empirical relationships, packaged in documented component models. Not having to describe the physics yourself represents a significant time and cost gain in your model-based design journey.

Figure 2:This model represents an aircraft’s true multi-physics system (from left to right): the airframe (mechanics), the power plant (traditionally, a mechanical-thermo-fluid system), and the auxiliary systems (fluids, electrical, etc.).

A technology geared towards physical system simulation brings the appropriate level of fidelity to make meaningful engineering decisions on systems and speaks the language of physics which helps manage model complexity. With the same model of a system, mechanical, fluid, heat transfer, electrical, chemical, and/or magnetic physical phenomena can be described effortlessly.

Physical System Simulation vs. Systems Engineering

Physical system simulation can be contrasted with systems engineering. Systems engineering is a paradigm that is primarily concerned with how different sub-systems and components interact without necessarily having any predictive capabilities of the behavior of each component or subsystem, and thus focuses on the requirements for successful interactions.

System Simulation Conclusion

While there are no strict guidelines on the use of any simulation paradigm over the other for a given simulation scenario, and there are many corner cases; each paradigm extends over a range that trades off the complexity and the engineer’s mission. There is no inherent preference for a given amount of detail in a model, rather there is the desire to pick the right modeling paradigm and model complexity for each task. Physical system simulation is paramount in making design decisions early in the design process, to support architecture and optimization; and later to validate verification tasks. Physical system simulation is also an excellent candidate for operational improvements for assets and to develop digital twins. Keep an eye out for more physical system simulation content including when to use physical system simulation, where it fits into your design process, and more.

Contact our experts to see physical system simulation in action!